Newly Developed Die - Casting Molds: Precision and Durability Guaranteed

2025-06-11 15:30

In the highly competitive landscape of modern manufacturing, the demand for components that combine precision, durability, and efficiency has never been greater. Die-casting, a process that involves injecting molten metal under high pressure into a mold cavity, has emerged as a cornerstone of advanced manufacturing. At the heart of this transformative process are die-casting molds, the unsung heroes that enable the production of complex, high-quality parts with unparalleled consistency. Our newly developed die-casting molds are designed to meet and exceed the stringent requirements of today’s industries, offering a perfect blend of precision engineering and robust durability.

The Science Behind Die-Casting Molds

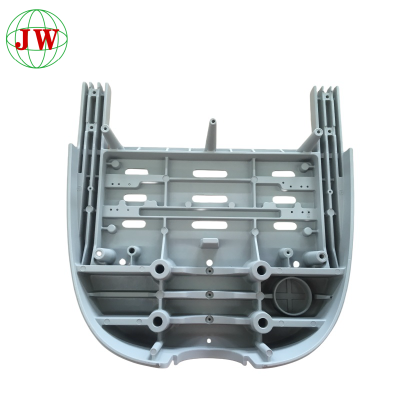

Die-casting molds serve as the blueprint for every die-cast component, dictating its shape, size, and surface finish. Crafted from high-grade tool steel, these moldsare engineered to withstand extreme pressures and temperatures during the die-casting process. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are employed to create molds with intricate geometries and tight tolerances. This meticulous design process ensures that each mold can produce components with consistent quality, reducing the margin of error and minimizing the need for post-processing adjustments.

One of the key features of our newly developed die-casting molds is their ability to handle a wide range of materials, including aluminum, zinc, and magnesium alloys. Each material has unique properties, and our molds are optimized to leverage these characteristics, ensuring that the final die-cast products meet the specific performance requirements of different applications. Whether it’s creating lightweight components for the automotive industry or durable parts for consumer electronics, our die-casting moldsare versatile enough to deliver outstanding results.

Precision: The Hallmark of Our Die-Casting Molds

Precision is non-negotiable in die-casting, and our molds are designed to deliver components with exacting accuracy. With tolerances as tight as ±0.01mm, these molds can produce parts with complex shapes and fine details that were once considered impossible to achieve. The use of advanced machining techniques, such as electrical discharge machining (EDM) and high-speed milling, ensures that the mold cavities are machined to perfection. This level of precision not only enhances the functionality of the die-cast components but also improves the overall efficiency of the manufacturing process by reducing assembly time and minimizing waste.

Moreover, our die-casting molds are equipped with advanced cooling systems that help regulate the temperature during the die-casting process. Proper cooling is essential for preventing defects, such as warping and shrinkage, and ensuring that the components maintain their dimensional stability. By optimizing the cooling channels within the mold, we can significantly reduce cycle times, increasing production rates without compromising on quality.

Durability: Built to Last

Durability is another critical aspect of our newly developed die-casting molds. These molds are constructed from high-quality tool steels that offer excellent wear resistance, toughness, and thermal stability. The materials are carefully selected and heat-treated to enhance their mechanical properties, ensuring that the molds can withstand the rigors of high-volume production. Additionally, the surface of the molds is often treated with coatings, such as titanium nitride (TiN) or diamond-like carbon (DLC), to further improve their hardness and reduce friction, extending their lifespan and reducing maintenance costs.

Our die-casting molds are also designed with modularity in mind. This means that individual components of the mold, such as inserts and slides, can be easily replaced or repaired without having to replace the entire mold. This not only saves time and money but also allows for greater flexibility in production, as different parts of the mold can be customized or modified to meet changing product requirements.

Applications Across Industries

The versatility of our die-casting molds makes them suitable for a wide range of industries. In the automotive sector, die-casting is widely used to produce engine components, transmission parts, and structural elements. Our molds enable the production of lightweight, high-strength aluminum alloy parts that contribute to improved fuel efficiency and performance. In the aerospace industry, where precision and reliability are paramount, our die-casting molds are used to create complex components for aircraft engines and airframes.

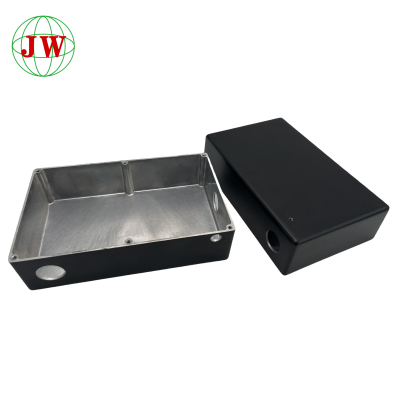

The consumer electronics industry also benefits greatly from the precision and durability of our die-casting molds. These molds are used to produce sleek, lightweight enclosures for smartphones, laptops, and other devices, providing both protection and aesthetic appeal. In addition, the furniture, medical, and industrial equipment sectors rely on die-cast components made from our molds to achieve high-quality, cost-effective production.

A Commitment to Innovation

We are constantly investing in research and development to improve the performance of our die-casting molds. By staying at the forefront of technological advancements, such as 3D printing for rapid prototyping and artificial intelligence for process optimization, we can offer our customers innovative solutions that meet the evolving needs of the manufacturing industry. Our team of experienced engineers and technicians works closely with clients to understand their specific requirements and develop customized die-casting mold solutions that deliver exceptional results.

In conclusion, our newly developed die-casting molds represent the pinnacle of precision and durability in the die-casting industry. With their advanced design, superior materials, and innovative features, these molds are poised to transform the way manufacturers produce high-quality components. Whether you’re looking to increase production efficiency, improve product quality, or reduce costs, our die-casting molds are the ideal choice for your manufacturing needs.

Get the latest price? We'll respond as soon as possible(within 12 hours)