Die Casting and Molds: Transforming Furniture Connectivity and Design

2025-05-30 15:35

In the dynamic world of furniture manufacturing, die casting and molds have emerged as pivotal elements, revolutionizing the way furniture is constructed, connected, and designed. As consumer demands for durable, stylish, and functional furniture continue to rise, the marriage of die casting technologyand precision molds is enabling manufacturers to create innovative, high-quality products that stand the test of time.

Precision and Durability in Connectivity

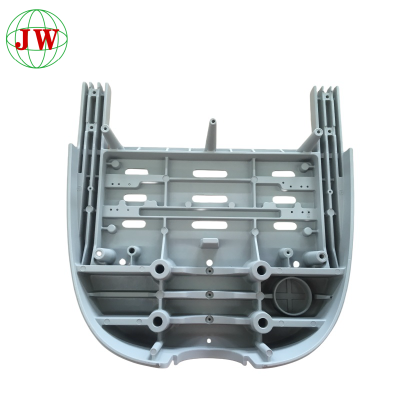

Furniture connectivity is the backbone of its structural integrity, and die-cast components are setting new standards in this regard. Whether it's the hinges that allow smooth opening and closing of cabinet doors, the connectors that hold together modular furniture units, or the brackets that support heavy shelves, die casting ensures a perfect fit and long-lasting strength.

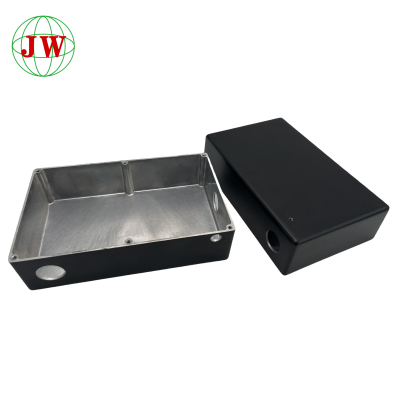

Manufacturers are increasingly turning to aluminum and zinc alloys for die-cast furniture connectors. Aluminum, with its lightweight yet robust nature, offers excellent corrosion resistance, making it ideal for both indoor and outdoor furniture. Zinc alloys, on the other hand, are prized for their high strength and ability to replicate intricate details, adding a touch of elegance to furniture designs.

The die-casting process, which involves injecting molten metal under high pressure into a mold cavity, allows for the creation of components with tight tolerances and consistent quality. This precision not only simplifies the assembly process but also reduces the risk of failure over time. In a market where consumers expect furniture to be both aesthetically pleasing and functional, die-cast connectors are proving to be a game-changer.

The Art and Science of Mold Making

Behind every successful die-cast furniture component lies a meticulously crafted mold. Mold making is a blend of art and science, requiring skilled technicians and advanced technology to create molds that can withstand the high pressures and temperatures of the die-casting process.

Modern mold making techniques, such as computer-aided design (CAD) and computer-aided manufacturing (CAM), have significantly enhanced the precision and efficiency of the process. CAD software allows designers to create detailed 3D models of molds, optimizing their design for maximum performance and minimizing the risk of defects. CAM technology then translates these digital designs into physical molds, using computer-controlled machining tools to achieve the highest level of accuracy.

The choice of mold material is also crucial in determining the quality and lifespan of die-cast components. Steel molds, for example, are known for their durability and ability to withstand repeated use, making them a popular choice for high-volume production. However, for more complex or intricate designs, molds made from specialized alloys or even ceramics may be used to achieve the desired level of detail.

Design Innovation and Customization

Die casting and molds are not only enhancing the functionality of furniture but also fueling design innovation and customization. With the ability to create complex shapes and geometries, furniture designers are no longer limited by traditional manufacturing constraints. They can now bring their most imaginative concepts to life, from sleek, modern designs to intricate, ornate pieces.

Customization is also becoming increasingly important in the furniture industry, and die casting offers a cost-effective solution for producing personalized components. By creating custom molds, manufacturers can produce small batches of unique furniture connectors or decorative elements, catering to the specific needs and preferences of individual customers. This level of customization is not only driving consumer satisfaction but also opening up new opportunities for furniture brands to differentiate themselves in a competitive market.

Sustainability and the Future of Furniture Manufacturing

In an era of increasing environmental awareness, sustainability is a key consideration in the furniture industry. Die casting and molds are playing an important role in promoting sustainable manufacturing practices, as many of the metals used in die casting, such as aluminum and zinc, are highly recyclable.

Manufacturers are also exploring ways to reduce the energy consumption and waste associated with the die-casting process. For example, some companies are using advanced cooling techniques to speed up the solidification of molten metal, reducing the overall production time and energy required. Others are implementing closed-loop systems that recycle and reuse excess metal, minimizing waste and reducing the environmental impact of production.

Looking to the future, the combination of die casting and molds is set to continue driving innovation in the furniture industry. As technology continues to advance, we can expect to see even more precise, efficient, and sustainable manufacturing processes, enabling the creation of furniture that is not only beautiful and functional but also environmentally friendly.

In conclusion, die casting and molds are the unsung heroes of the furniture manufacturing industry, enabling the production of high-quality, durable, and innovative furniture that meets the evolving needs of consumers. As the industry continues to evolve, these technologies will undoubtedly play an even more significant role in shaping the future of furniture design and production.

Get the latest price? We'll respond as soon as possible(within 12 hours)