Aluminum Die-Casting Industry Thrives: Powering New Energy, Advanced Manufacturing, and Sustainable Production

2025-10-20 15:30

The aluminum die-casting industry has emerged as a linchpin of modern manufacturing, leveraging aluminum’s unique blend of light weight, strength, and recyclability to meet the demands of fast-growing sectors like new energy vehicles (NEVs), renewable energy, and consumer electronics. As global markets prioritize efficiency and sustainability, aluminum die-casting has moved beyond a niche process to a mainstream solution—driving innovation, reducing carbon footprints, and enabling the production of complex, high-performance components. In 2024, the global aluminum die-casting market was valued at

42billion,withprojectionstoreach

65 billion by 2030, boasting a CAGR of 7.6%—outpacing the broader die-casting sector, according to a report by Allied Market Research. This growth is fueled by three core pillars: surging demand from NEVs, expansion into renewable energy, and breakthroughs in casting technology.

NEVs: The Unrivaled Driver of Aluminum Die-Casting Demand

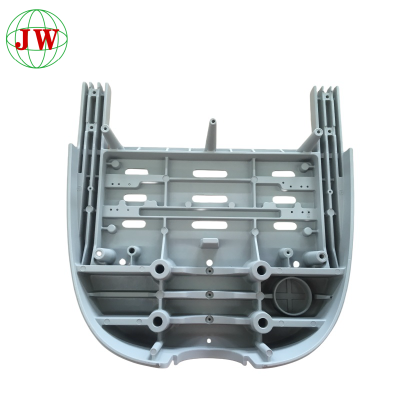

The new energy vehicle (NEV) sector is the single largest catalyst for the aluminum die-casting industry. NEVs rely on lightweight components to extend battery range, and aluminum—being 30% lighter than steel—has become the material of choice for critical parts like battery housings, motor casings, and inverter enclosures. Unlike traditional steel components, aluminum die-cast partscan be manufactured in near-net shapes, minimizing waste and reducing assembly time—a key advantage for high-volume NEV production.

Tesla’s “Giga Press” technology has been a game-changer, popularizing the use of large-format aluminum die-casting for NEV chassis. By producing entire rear underbodies in one piece (using aluminum alloys like Al-Si-Mg-Cu), Tesla eliminates over 70 welding points, cuts production costs by 20%, and reduces vehicle weight by 15kg. This innovation has spurred competitors: BYD, the world’s top NEV maker, now uses aluminum die-cast chassis for its Han EV series, while Volkswagen plans to equip 80% of its NEVs with aluminum die-cast battery housings by 2027.

Demand for specialized aluminum alloys is also rising. NEV battery housings require alloys with high impact resistance and thermal conductivity—properties that protect batteries from damage and dissipate heat during charging. Alloys like AA6061 and AA5083 have become industry standards, with suppliers like Novelis and Constellium reporting a 60% year-over-year increase in orders for NEV-specific aluminum grades. In 2023 alone, NEVs accounted for 52% of global aluminum die-casting demand, up from 28% in 2019.

Renewable Energy: Aluminum Die-Casting Expands Beyond Automotive

While NEVs dominate, the renewable energy sector is fast becoming a major growth engine for aluminum die-casting. Solar, wind, and energy storage systems require durable, corrosion-resistant components that can withstand harsh outdoor conditions—and aluminum die-cast parts deliver on all fronts.

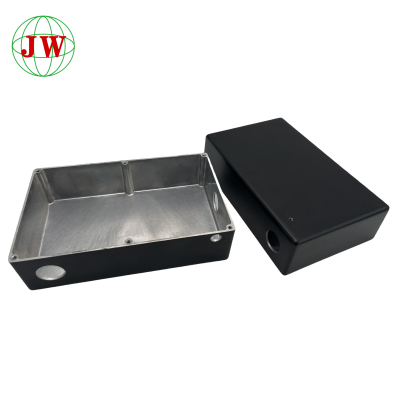

In solar energy, aluminum die-cast mounting brackets and inverter enclosures are essential. These parts must resist UV radiation, rain, and temperature fluctuations (from -40°C to 85°C) while supporting the weight of solar panels. Companies like First Solar use aluminum die-cast brackets for their utility-scale solar farms, as they offer 50% more corrosion resistance than steel brackets and require minimal maintenance. The global market for aluminum die-cast solar components is expected to grow at a 10.2% CAGR through 2030, driven by the expansion of solar capacity in China, India, and the U.S.

Wind energy is another key area. Wind turbine generators rely on aluminum die-cast motor housings and gearbox casings that can handle high rotational speeds and heavy loads. Aluminum’s lightweight properties reduce the stress on turbine shafts, improving energy efficiency, while its thermal conductivity helps cool generators during operation. Vestas, a leading wind turbine manufacturer, has switched to aluminum die-cast casings for its 4MW turbines, cutting turbine weight by 8% and boosting power output by 3%.

Energy storage systems (ESS) also depend on aluminum die-casting. ESS battery packs need aluminum die-cast enclosures that are fire-resistant and leak-proof—critical for safety in residential and commercial settings. Chinese ESS maker CATL uses aluminum die-cast enclosures for its home battery systems, as they meet global safety standards (like UL 94 V-0) and can be mass-produced at low cost.

Technological Breakthroughs: Making Aluminum Die-Casting More Efficient and Sustainable

Advancements in casting technology are further propelling the aluminum die-casting industry, addressing historical challenges like porosity (air bubbles in parts) and high energy consumption.

Vacuum Die-Casting has become a standard for NEV and aerospace components. This process removes air from the mold cavity before injecting molten aluminum, reducing porosity by 90% and improving part strength. Japanese die-caster Toyoda Gosei uses vacuum die-casting for NEV inverter casings, ensuring the parts can withstand high voltages (up to 800V) without leaking. Vacuum die-casting has also cut defect rates for aluminum parts from 8% to 2%, saving manufacturers millions in rework costs.

AI-Powered Process Control is another innovation. By integrating sensors and machine learning into die-casting machines, manufacturers can monitor key parameters (like molten aluminum temperature, injection speed, and mold pressure) in real time. AI algorithms adjust these parameters automatically to optimize quality—for example, reducing injection speed if the metal is cooling too quickly. German die-casting firm Bühler’s “AI Casting Suite” has helped customers increase production efficiency by 15% and reduce energy use by 12% per part.

Sustainability is also a focus. The aluminum die-casting process is inherently recyclable—up to 95% of scrap aluminum (from trim edges or defective parts) can be melted and reused. But recent advances in closed-loop recycling have taken this further: NEV makers like BMW now collect scrap aluminum from their die-casting plants, melt it down, and reuse it to make new battery housings. This process reduces carbon emissions by 92% compared to using virgin aluminum, aligning with global net-zero goals. Some die-casters are even using low-carbon aluminum (produced with renewable energy) for high-end parts, further cutting their environmental impact.

Challenges and Opportunities Ahead

Despite its growth, the aluminum die-casting industry faces hurdles. Volatility in aluminum prices (driven by global supply chains and energy costs) has squeezed profit margins for some manufacturers. Additionally, the high upfront cost of large-format die-casting machines (which can exceed $3 million) is a barrier for small and medium-sized enterprises (SMEs).

However, opportunities abound. The expansion of NEV charging infrastructure—requiring aluminum die-cast charging station enclosures and connectors—will create new demand. The rise of “urban air mobility” (e.g., electric flying taxis) will also drive need for lightweight aluminum die-cast components. Moreover, governments are supporting the industry: the U.S. Inflation Reduction Act offers tax credits for manufacturers using recycled aluminum in die-cast parts, while China’s “14th Five-Year Plan” includes subsidies for aluminum die-casters investing in green technology.

Conclusion

The aluminum die-casting industry is in the midst of a historic boom, driven by its irreplaceable role in NEVs, renewable energy, and advanced manufacturing. Its ability to combine light weight, strength, and sustainability makes it a cornerstone of the global shift toward greener, more efficient production. As technology continues to advance and new applications emerge, aluminum die-casting will not just grow—it will redefine how the world builds the products that power modern life. For businesses in the sector, adapting to these trends will mean not just surviving, but thriving in a market where innovation and sustainability go hand in hand

Get the latest price? We'll respond as soon as possible(within 12 hours)