What are our solutions for large-scale production of furniture components?

2025-06-30 17:34

In the realm of furniture manufacturing, large-scale production of components demands precision, efficiency, and scalability. Our solutions integrate advanced die-casting technologies, intelligent automation, and innovative mold design to address the challenges of high-volume production while maintaining uncompromised quality. Below are the core strategies that enable us to deliver consistent, cost-effective furniture components at scale.

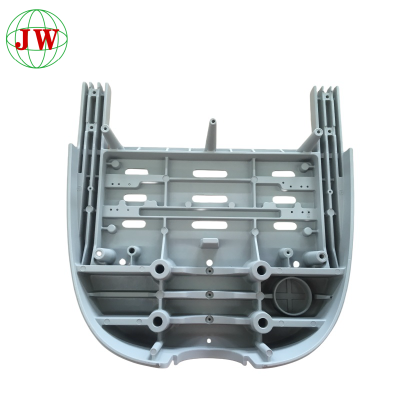

1. Advanced Aluminum Die-Casting for Mass Production

At the heart of our large-scale solutions lies aluminum die-casting, a process that combines speed and precision. By injecting molten aluminum alloys (such as A380 or ADC12) under high pressure into die-casting molds, we achieve components with tight tolerances (±0.05mm) and minimal post-processing. This method is ideal for furniture connectors, brackets, and structural parts, offering:

High productivity: Automated die-casting cells can produce 500+ parts per hour, reducing cycle times by 40% compared to traditional casting.

Material efficiency: Aluminum’s recyclability ensures minimal waste, with 95% of scrap material reusable for subsequent production runs.

Design flexibility: Complex geometries, including undercuts and integrated features, can be cast in one piece, eliminating assembly steps.

Die-casting molds are engineered from high-grade tool steels (e.g., H13) with conformal cooling channels, ensuring uniform solidification and extending mold life to 500,000+ cycles—critical for maintaining consistency in large batches.

2. Intelligent Automation and Robotics

To optimize large-scale production, we deploy fully automated lines featuring:

Robotic handling systems: Industrial robots load/unload die-cast components from molds, perform deburring, and inspect surface finishes with 99.8% accuracy.

AI-powered process control: Sensors monitor injection pressure, temperature, and cycle time in real-time, adjusting parameters to prevent defects. This reduces rejection rates to below 0.5%.

Digital twin technology: Virtual models of production lines simulate mass production scenarios, identifying bottlenecks and optimizing workflow before physical deployment.

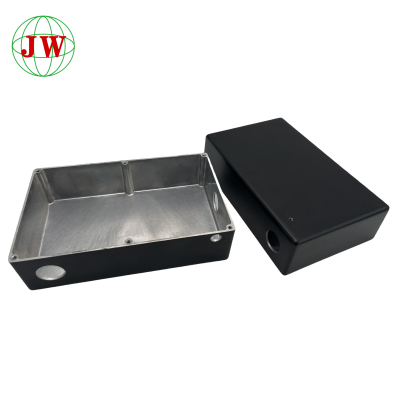

For example, our automated powder coating stations use robotic arms to apply finishes (e.g., black powder coat) with consistent thickness (60-80μm), meeting high-volume demands while adhering to quality standards like RAL color specifications.

3. Modular Mold Design for Versatility

Our die-casting molds are designed with modularity in mind, enabling quick adaptation to different furniture component designs:

Multi-cavity molds: Single molds with multiple cavities (e.g., 8-cavity for small connectors) increase output without sacrificing precision.

Interchangeable inserts: Core components of the mold can be swapped to produce different part variants, reducing tooling costs by up to 30% for product line expansions.

Rapid prototyping: 3D-printed mold prototypes allow us to test design feasibility within days, accelerating the transition from concept to mass production.

This approach ensures that whether producing 10,000 chair legs or 100,000 cabinet hinges, our mold design remains flexible and cost-efficient.

4. Streamlined Supply Chain and Quality Control

Large-scale production requires robust supply chain management:

Vertical integration: In-house casting, machining, and finishing capabilities minimize dependency on external vendors, reducing lead times by 50%.

Certified material sourcing: Aluminum alloys are sourced from ISO 9001-certified suppliers, with each batch tested for chemical composition and mechanical properties (e.g., tensile strength, elongation).

Comprehensive quality checks: Every component undergoes:

Visual inspection for surface defects

Dimensional verification via CMM (coordinate measuring machines)

Salt spray testing (500+ hours) for corrosion resistance

This end-to-end control ensures that furniture components meet international standards (e.g., ASTM, EN) even at the highest production volumes.

5. Sustainable Manufacturing Practices

To support eco-friendly large-scale production, we prioritize:

Energy-efficient casting: Induction furnaces reduce energy consumption by 30% compared to traditional heating methods.

Waste reduction: Recycled aluminum minimizes raw material usage, while scrap from machining is repurposed within the production cycle.

Lean manufacturing principles: Just-in-time (JIT) production reduces inventory waste, and continuous process improvement (CPI) eliminates non-value-added steps.

Conclusion: Scaling Excellence in Furniture Components

Our solutions for large-scale production of furniture components blend technological innovation with operational efficiency. By leveraging advanced die-casting, intelligent automation, modular mold design, and rigorous quality control, we enable manufacturers to meet high-volume demands without compromising on precision or sustainability. Whether for residential, commercial, or contract furniture, our approach ensures that every component—from connectors to structural parts—meets the highest standards of durability, functionality, and cost-effectiveness at scale.

Get the latest price? We'll respond as soon as possible(within 12 hours)