Aluminum Die-Cast Parts & Molds: Symbiotic Innovation Drives Automotive, Renewable, and Tech Sectors

2025-10-17 15:30

The global manufacturing ecosystem relies on a critical partnership: aluminum die-cast partsand the aluminum die-casting moldsthat shape them. This symbiosis—where mold precision directly dictates part quality—has become the backbone of industries chasing efficiency, sustainability, and complex design. As demand for lightweight, high-performance components surges (led by electric vehicles and renewables), both aluminum die-cast partsand their molds are undergoing rapid innovation. In 2024, the combined market for aluminum die-cast parts and molds reached $58 billion, with forecasts to hit $91 billion by 2030 (a CAGR of 7.9%), according to a study by Grand View Research. This growth is fueled by three interconnected trends: mold technology advancements, cross-sector part demand, and a shared focus on sustainability.

Aluminum Die-Casting Molds: Precision Engineering Redefines Part Possibilities

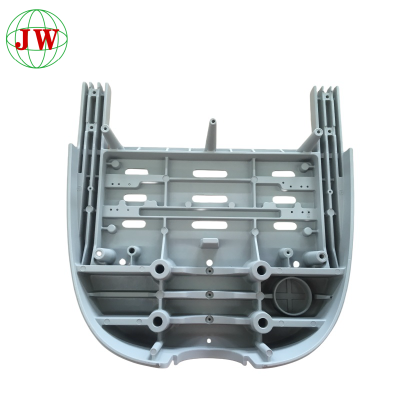

Aluminum die-casting molds are no longer just tools—they are engineered systems that determine the strength, dimensional accuracy, and production efficiency of aluminum die-cast parts. Modern molds must withstand extreme conditions: molten aluminum reaches 660°C (1,220°F), and high-pressure die-casting (HPDC) machines exert clamping forces up to 4,000 tons. To meet these demands, mold manufacturers are adopting new materials, designs, and technologies.

Material innovation leads the charge. Traditional molds use H13 hot-work steel, but new alloys like STAVAX ESR (a stainless steel variant) offer 30% better corrosion resistance—critical for producing parts like EV battery housings, which require zero rust or contamination. For high-volume production (e.g., 500,000+ parts per mold), powder metallurgy (PM) steel is gaining traction; its uniform grain structure reduces wear, extending mold lifespan from 300,000 cycles to 500,000 cycles. Suppliers like Hasco and DME report a 45% year-over-year increase in orders for PM steel molds, driven by EV manufacturers.

Design breakthroughs are equally impactful. Conformal cooling channels—3D-printed into mold cores—revolutionize heat dissipation. Unlike traditional straight channels, these curved paths follow the mold’s shape, reducing part cooling time by 25% and minimizing warpage (a common issue with aluminum parts). For example, German mold maker Georg Kaufmann uses conformal cooling in molds for aluminum die-cast EV motor casings, cutting production cycles from 90 seconds to 65 seconds.

Digitalization further elevates mold performance. Computer-Aided Engineering (CAE) software simulates molten aluminum flow, identifying air traps or thin walls before mold production. This “virtual testing” reduces mold iterations by 40%, saving manufacturers months of development time. Tesla’s Giga Press molds, which produce 1.5-meter-long aluminum die-cast chassis parts, rely on CAE to ensure uniform metal distribution—critical for avoiding structural weak points.

Aluminum Die-Cast Parts: Cross-Sector Demand Transforms Manufacturing

Aluminum die-cast parts are expanding beyond automotive, finding homes in renewables, consumer electronics, and even medical devices. Their appeal lies in aluminum’s unique properties: 40% lighter than steel, 100% recyclable, and capable of complex shapes (e.g., hollow cores, intricate textures) that machining cannot match.

The EV sector remains the top consumer. Aluminum die-cast parts like battery housings, inverter casings, and suspension components are essential for extending range and ensuring safety. BYD’s Seal EV uses 12 aluminum die-cast parts in its chassis, reducing weight by 20kg and improving energy efficiency by 6%. Even luxury EV makers like Lucid rely on aluminum die-cast parts—its Air sedan’s rear bulkhead is a single die-cast component, eliminating 40+ welds and boosting structural rigidity.

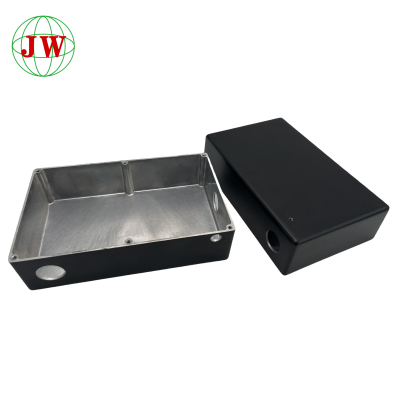

Renewable energy is a fast-growing segment. Solar inverters use aluminum die-cast enclosures to protect electronics from weather, while wind turbines depend on aluminum die-cast gearbox housings to handle high torque. First Solar’s utility-scale solar farms use aluminum die-cast mounting brackets, which resist saltwater corrosion (critical for coastal sites) and last 25+ years. In 2023, renewables accounted for 18% of aluminum die-cast part demand, up from 8% in 2019.

Consumer electronics are another key market. 5G routers, laptop bases, and smart home devices use small, precise aluminum die-cast parts. Apple’s Mac Studio desktop uses an aluminum die-cast chassis—its seamless design (enabled by advanced molds) improves heat management and durability. For these parts, zinc-aluminum hybrid die-casting (combining aluminum’s lightness with zinc’s precision) is emerging, allowing for parts as small as 5mm with tolerances of ±0.02mm.

Shared Sustainability Goals: Molds and Parts Drive Circular Manufacturing

Sustainability is unifying the aluminum die-cast parts and mold industries, with both focusing on waste reduction, energy efficiency, and recyclability.

For aluminum die-cast parts, recycling is a competitive advantage. Up to 95% of scrap aluminum (from trim edges or defective parts) can be melted and reused—requiring just 5% of the energy needed to produce virgin aluminum. BMW’s Munich die-casting plant operates a closed-loop system: scrap from battery housing production is recycled into new parts, cutting carbon emissions by 85%. Even end-of-life parts are repurposed—old EV aluminum die-cast chassis are melted down to make new solar brackets, creating a circular supply chain.

Aluminum die-casting molds are also becoming greener. Mold manufacturers are using recycled steel in mold frames (reducing embodied carbon by 40%) and developing “modular molds”—where worn cores can be replaced instead of discarding the entire mold. Chinese mold maker Haitian Precision’s modular molds cut waste by 35% and extend mold life by 50%, as only damaged components are swapped out.

Energy efficiency is another focus. Electric die-casting machines (replacing gas-powered ones) reduce mold heating energy use by 30%, while AI-powered mold temperature control systems optimize heat distribution—cutting overall process energy consumption by 15%. These innovations align with global climate goals: the EU’s Carbon Border Adjustment Mechanism (CBAM) now rewards manufacturers using low-carbon aluminum die-cast parts and molds with lower tariffs.

Challenges and Opportunities for Symbiotic Growth

Despite progress, both industries face hurdles. The high cost of advanced molds (up to $1 million for large EV chassis molds) limits small manufacturers’ access. Additionally, a global shortage of mold designers (skilled in CAE and 3D printing) slows innovation, with NADCA reporting a 28% gap in qualified talent.

Yet opportunities abound. The rise of small-batch die-casting (for custom EV parts or medical devices) is driving demand for “quick-change molds”—which can switch between part designs in 30 minutes, up from 4 hours. For aluminum die-cast parts, aluminum-lithium alloys (10% lighter than standard aluminum) are opening new markets, such as aerospace (e.g., lightweight satellite components).

Policy support further boosts growth. The U.S. CHIPS and Science Act offers grants for aluminum die-cast part production for semiconductors, while China’s “New Energy Vehicle Industry Development Plan” subsidizes mold innovation for EV parts. These policies recognize that aluminum die-cast parts and molds are not just components—they are enablers of a more sustainable, efficient manufacturing future.

Conclusion

The partnership between aluminum die-cast parts and aluminum die-casting molds is reshaping global manufacturing. As molds become more precise and durable, they unlock complex part designs; as parts find new uses in EVs, renewables, and tech, they drive demand for better molds. Together, they are proving that sustainability and performance can coexist—creating a manufacturing ecosystem that is lighter, greener, and more innovative. For businesses in this space, investing in this symbiosis is not just a strategic choice—it is the key to thriving in a world where efficiency and sustainability are no longer optional, but essential.

Get the latest price? We'll respond as soon as possible(within 12 hours)