Aluminum Building Die-Castings: Reshaping Modern Construction with Strength and Sustainability

2025-08-13 16:49

Aluminum Building Die-Castings: Reshaping Modern Construction with Strength and Sustainability

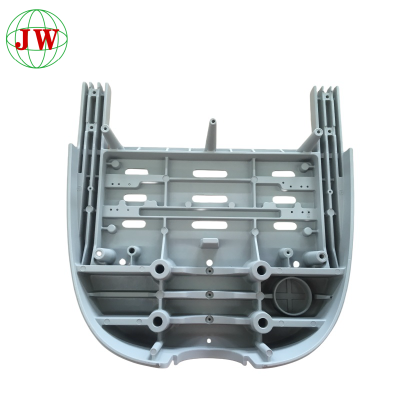

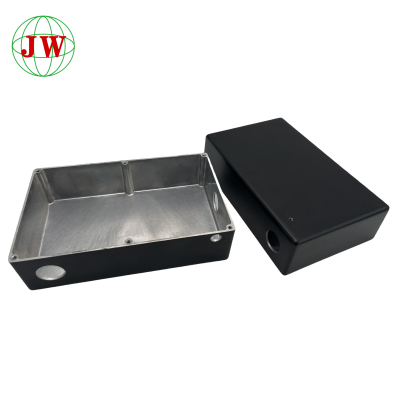

In the realm of contemporary architecture, aluminum building die-castings have emerged as a transformative force, redefining how structures are designed, built, and maintained. These precision-engineered components, born from advanced die-casting processes, combine durability, versatility, and eco-friendliness to meet the evolving demands of the construction industry—from towering skyscrapers to sustainable green buildings.

The Advantages of Aluminum in Construction Die-Castings

Aluminum has become a material of choice for building components, thanks to its unique properties that address key challenges in construction. Unlike steel, which is heavy and prone to corrosion, or concrete, which lacks flexibility, aluminum offers a compelling blend of lightweight strength, resistance to the elements, and malleability.

Building die-castings—such as curtain wall brackets, window frames, and structural connectors—leverage these traits to enhance both functionality and efficiency. For example, aluminum die-castcurtain wall brackets can support large glass panels while adding minimal weight to a building’s facade, reducing overall structural load. Their corrosion resistance also makes them ideal for coastal or industrial areas, where salt or pollution might degrade traditional materials.

How Die-Casting Elevates Building Components

The die-casting process is critical to unlocking aluminum’s potential in construction. By injecting molten aluminum alloy (typically 6061 or A356, chosen for their strength and castability) into precision steel molds under high pressure (up to 12,000 psi), manufacturers produce building die-castings with:

Complex Designs: Die-casting allows for intricate shapes—such as hollow cores, threaded inserts, and custom contours—that are impossible or cost-prohibitive with welding or machining. This enables architects to create sleek, modern designs, like curved window frames or minimalist structural supports, without sacrificing strength.

Consistent Quality: Each die-cast component is nearly identical, with tolerances as tight as ±0.03mm. This uniformity is vital for modular construction, where prefabricated parts must align perfectly on-site, reducing assembly time and errors.

Enhanced Structural Integrity: The high-pressure process eliminates air bubbles and ensures even material distribution, giving aluminum building die-castings tensile strength up to 290 MPa—strong enough to withstand wind loads, seismic activity, and long-term wear.

Key Applications in Modern Buildings

Aluminum building die-castings are integral to various parts of construction, from exterior facades to internal systems:

Curtain Walls and Façades: Die-cast aluminum brackets and clips secure glass, stone, or metal panels, creating energy-efficient, weatherproof exteriors. These components support large spans while allowing for thermal expansion, preventing cracks or leaks in extreme temperatures.

Structural Connectors: Aluminum die-cast joist hangers, beam brackets, and truss connectors link structural elements with precision, ensuring stability in roofs, floors, and load-bearing walls. Their lightweight design eases transportation and on-site handling, speeding up construction.

Window and Door Systems: Die-cast aluminum frames and hinges offer superior insulation and durability compared to plastic or wood, reducing energy loss in buildings. They also resist warping or rotting, extending the lifespan of windows and doors by 15–20 years.

Innovation and Sustainability in Die-Casting

Advancements in die-casting technology are expanding the role of aluminum in construction. Large-scale die-casting machines now produce components weighing up to 50kg, enabling the creation of integrated structural parts that replace multiple welded steel pieces. This reduces material waste by 30% and cuts carbon emissions from manufacturing.

Sustainability is another key driver. Aluminum is 100% recyclable, and building die-castings often use recycled alloy (up to 80% in some cases), which requires 95% less energy than producing primary aluminum. This aligns with global green building standards, such as LEED and BREEAM, making aluminum die-cast components a favorite among eco-conscious developers.

Market Growth and Future Trends

The global market for aluminum building die-castings is booming, valued at $7.3 billion in 2023 and projected to grow at 6.9% annually through 2030. This growth is fueled by the rise of modular construction, urbanization, and the push for energy-efficient buildings.

Future innovations include smart die-cast components embedded with sensors to monitor structural stress or temperature changes, enabling predictive maintenance. 3D-printed molds are also reducing prototyping time, allowing architects to test custom designs faster than ever.

Conclusion

Aluminum building die-castings are more than just parts—they are the backbone of modern, sustainable construction. By combining the strength of aluminum, the precision of die-casting, and a commitment to eco-friendliness, these components are helping build safer, more efficient, and visually striking structures. As the industry continues to prioritize innovation and sustainability, aluminum die-castings will remain at the forefront of architectural progress.

Get the latest price? We'll respond as soon as possible(within 12 hours)