Aluminum Die-Cast Building Accessories: Innovation and Sustainability Reshape Construction Sector

2026-01-30 15:30

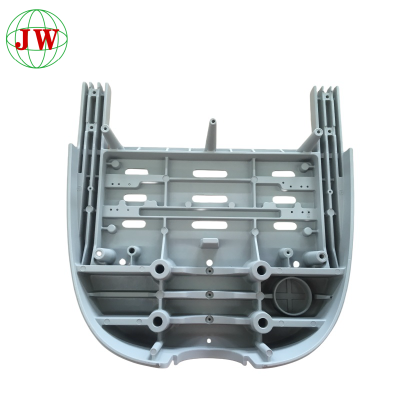

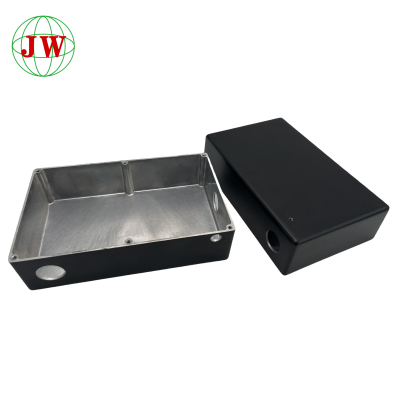

The global construction industry is embracing a new era of efficiency and aesthetics driven by aluminum die-cast accessories. As essential components in modern buildings, die-cast building accessories—ranging from door hinges and curtain wall connectors to decorative frames—leverage aluminum’s lightweight, corrosion-resistant properties and advanced die-casting technology to balance structural integrity and design flexibility. Fueled by green building policies, urban renewal projects, and demand for durable, low-maintenance components, the market for aluminum die-cast building accessories is expanding steadily. Grand View Research data shows the global market is valued at $8.7 billion, with a CAGR of 6.6% projected over the forecast period, reaching $12.8 billion by the end of the period <superscript:4.

Aluminum die-cast accessories dominate the die-cast building accessories market, accounting for over 65% of global shipments due to their superior performance<superscript:2. High-strength aluminum alloys such as A356 and ADC12 are widely adopted for structural parts, offering excellent die-casting fluidity and tensile strength to withstand heavy loads. For example, aluminum die-cast hinges for high-end doors can endure over 150,000 openings and closings, meeting the rigorous durability requirements of commercial buildings <superscript:2. Decorative aluminum die-cast accessories, such as window frames and balcony railings, showcase remarkable design versatility—architects can achieve smooth, matte, or textured finishes to match diverse architectural styles <superscript:1.

Technological advancements in die-casting are elevating the quality and precision of die-cast building accessories. High-pressure die-casting and semi-solid molding technologies have become mainstream, enabling one-piece molding of complex structures with dimensional tolerance controlled within ±0.02mm <superscript:2. Intelligent production systems, including MES platforms and industrial robots, are widely integrated, boosting the industry’s digital penetration rate to 31% <superscript:2. 3D printing sand casting technology has shortened die-casting mold development cycles by 40%, allowing enterprises to quickly respond to customized orders for non-standard aluminum die-cast accessories<superscript:2.

Sustainability has become a core driver of industry transformation, with green policies and recycled materials reshaping production models. The use of recycled aluminum in aluminum die-cast building accessories has risen to 38%, reducing carbon emissions per unit product by 41.2% compared to primary aluminum <superscript:3. Enterprises are replacing traditional coal-fired furnaces with electric induction melting equipment, cutting unit energy consumption by 19.7% <superscript:3. Environmental surface treatments like nanocoatings extend the salt spray resistance of aluminum die-cast accessories to 1200 hours, enhancing durability in harsh environments <superscript:2.

The Asia-Pacific region leads the global die-cast building accessories market, with China as the key growth engine. Benefiting from mature die-casting technology and robust demand from urban renewal and high-end real estate projects, Chinese enterprises supply over 45% of global aluminum die-cast building accessories<superscript:4. The East China region, including Jiangsu, Zhejiang, and Shandong provinces, contributes 45% of national output, forming a complete industrial chain from material smelting to die-casting and surface treatment <superscript:3. In Europe, strict environmental standards and demand for energy-efficient buildings drive growth in high-performance aluminum die-cast accessories<superscript:4.

Market demand is diversifying with the rise of smart buildings and customized architecture. Intelligent aluminum die-cast accessories integrated with sensors and damping systems are gaining traction, with the smart hinge market expected to reach $3 billion <superscript:2. Customized die-cast building accessories for luxury hotels and boutique residences are in high demand, with enterprises offering one-stop services from design to die-casting and installation <superscript:3. The photovoltaic sector has emerged as a new growth point, with aluminum die-cast brackets seeing 68% shipment growth <superscript:2.

Looking ahead, the aluminum die-cast building accessories industry will focus on precision upgrading, green material innovation, and intelligent integration. As policies promote low-carbon construction and smart cities, die-cast building accessories will evolve toward multi-functionality and integration. Enterprises mastering core die-casting technologies and recycled material utilization will gain a competitive edge, driving the construction industry toward sustainable and high-end development.

Get the latest price? We'll respond as soon as possible(within 12 hours)