Unleashing Precision and Performance: The Power of Aluminum Alloy Die-Casting and Molds

2025-06-20 15:00

In the ever-evolving landscape of modern manufacturing, aluminum alloy die-castinghas emerged as a revolutionary force, redefining the standards of precision, durability, and efficiency. From automotive components to aerospace structures, aluminum alloy castingsand aluminum alloy die-castingshave become the cornerstone of countless industries, enabling the production of complex, high-performance parts with unparalleled consistency. At the heart of this transformative process lies the die-casting mold, a marvel of engineering that shapes molten aluminum into intricate forms with pinpoint accuracy. This comprehensive article delves into the world of aluminum alloy die-casting and molds, exploring their key features, benefits, applications, and technological advancements.

The Art and Science of Aluminum Alloy Die-Casting

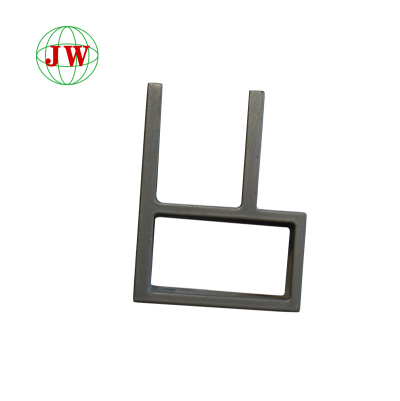

Aluminum alloy die-casting is a highly specialized manufacturing process that involves injecting molten aluminum alloy under high pressure into a die-casting mold. The mold, typically made from high-grade tool steel, is designed to create a cavity that precisely matches the shape of the desired aluminum alloy casting. Once the molten metal fills the cavity, it solidifies rapidly, taking on the exact form of the mold. This process allows for the production of aluminum alloy die-castings with exceptional dimensional accuracy, smooth surface finishes, and complex geometries that are difficult or impossible to achieve through traditional manufacturing methods.

The Role of Aluminum Alloys

Aluminum alloys are the ideal choice for die-casting due to their unique combination of properties. They are lightweight, yet strong and durable, making them suitable for a wide range of applications. Additionally, aluminum alloys have excellent thermal conductivity, which allows for efficient heat dissipation, and they are highly resistant to corrosion, ensuring long-term performance even in harsh environments. Some of the most commonly used aluminum alloys in die-casting include A380, A383, and ADC12, each of which offers a specific set of characteristics tailored to different applications.

The Importance of Die-Casting Molds

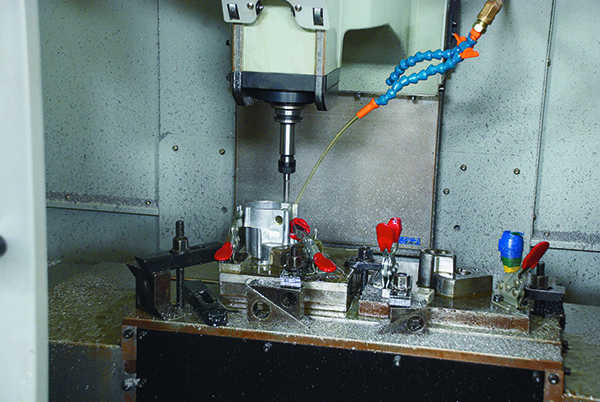

Die-casting molds are the key to achieving high-quality aluminum alloy castings. They must be able to withstand the high pressures and temperatures generated during the die-casting process, while also ensuring that the molten metal fills the cavity completely and solidifies evenly. To meet these demanding requirements, die-casting molds are typically made from high-strength tool steels, such as H13, which offer excellent wear resistance, toughness, and thermal stability. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are used to create molds with intricate geometries and tight tolerances, ensuring that each aluminum alloy die-casting meets the strictest quality standards.

Key Benefits of Aluminum Alloy Die-Casting and Molds

Precision and Dimensional Accuracy

One of the primary advantages of aluminum alloy die-casting is its ability to produce parts with exceptional precision and dimensional accuracy. The high-pressure injection of molten metal into the die-casting mold ensures that the aluminum alloy casting conforms to the exact shape and dimensions of the mold cavity, resulting in parts with tight tolerances and consistent quality. This precision eliminates the need for extensive post-machining operations, saving both time and cost in the manufacturing process.

Design Flexibility

Aluminum alloy die-casting offers unparalleled design flexibility, allowing for the creation of complex shapes and geometries that are difficult or impossible to achieve through traditional manufacturing methods. The use of advanced CAD/CAM technologies enables designers to create intricate mold designs with features such as thin walls, undercuts, and internal passages, which can be easily replicated in the aluminum alloy casting. This design flexibility makes aluminum alloy die-castings ideal for applications where aesthetics, functionality, and performance are all critical factors.

Cost-Effectiveness

Despite its high level of precision and quality, aluminum alloy die-casting is a cost-effective manufacturing process. The ability to produce parts with minimal post-machining reduces labor costs and production time, while the use of recyclable aluminum alloys helps to minimize material waste. Additionally, the high-volume production capabilities of die-casting make it an ideal choice for applications where large quantities of parts are required, further reducing the per-unit cost of production.

Durability and Performance

Aluminum alloy castings and aluminum alloy die-castings are known for their exceptional durability and performance. The high-strength properties of aluminum alloys, combined with the precise control of the die-casting process, result in parts that can withstand high mechanical stresses, thermal cycling, and corrosion. This makes them suitable for a wide range of applications, from automotive engines and transmissions to aerospace structures and consumer electronics.

Applications of Aluminum Alloy Die-Casting and Molds

Automotive Industry

The automotive industry is one of the largest consumers of aluminum alloy die-castings, with applications ranging from engine blocks and cylinder heads to transmission cases and suspension components. The lightweight properties of aluminum alloys help to improve fuel efficiency and reduce emissions, while their high strength and durability ensure reliable performance under demanding operating conditions. Additionally, the precision and design flexibility of aluminum alloy die-casting allow for the creation of complex engine components with optimized geometries, improving performance and reducing noise, vibration, and harshness (NVH).

Aerospace Industry

In the aerospace industry, aluminum alloy die-castings are used extensively for applications such as aircraft structures, engine components, and landing gear. The high strength-to-weight ratio of aluminum alloys makes them ideal for aerospace applications, where weight reduction is critical for improving fuel efficiency and performance. Additionally, the corrosion resistance and durability of aluminum alloy castings ensure long-term reliability in the harsh environments encountered during flight.

Consumer Electronics

The consumer electronics industry also benefits greatly from the use of aluminum alloy die-castings, with applications ranging from smartphone and tablet casings to laptop frames and computer components. The lightweight and durable properties of aluminum alloys make them ideal for portable devices, while their excellent thermal conductivity helps to dissipate heat generated by high-performance electronics. Additionally, the precision and design flexibility of aluminum alloy die-casting allow for the creation of sleek, stylish designs that meet the aesthetic demands of consumers.

Industrial Equipment

Aluminum alloy die-castings are widely used in the production of industrial equipment, such as pumps, valves, and hydraulic components. The high strength and corrosion resistance of aluminum alloys make them suitable for applications where reliability and durability are critical, while their lightweight properties help to reduce the overall weight of the equipment, improving efficiency and reducing energy consumption.

Technological Advancements in Aluminum Alloy Die-Casting and Molds

3D Printing and Rapid Prototyping

The integration of 3D printing technology in die-casting mold development has revolutionized the aluminum alloy die-casting industry. 3D printing allows for the rapid prototyping of molds, reducing the time and cost associated with traditional mold-making processes. This technology enables designers to quickly test and refine their designs, accelerating the product development cycle and bringing new products to market faster.

Smart Manufacturing and Automation

Modern aluminum alloy die-casting facilities are increasingly adopting smart manufacturing technologies, such as robotics and artificial intelligence (AI), to improve efficiency, quality, and productivity. Automated die-casting machines equipped with sensors and AI algorithms can monitor and optimize the production process in real-time, ensuring consistent quality and minimizing downtime. Additionally, the use of robotics for tasks such as mold handling, part removal, and post-processing reduces labor costs and improves safety in the workplace.

Advanced Mold Materials and Coatings

The development of advanced mold materials and coatings has significantly improved the performance and lifespan of die-casting molds. Newer mold materials, such as high-speed steels and carbide composites, offer improved wear resistance, toughness, and thermal stability, allowing for longer mold life and reduced maintenance costs. Additionally, advanced coatings, such as titanium nitride (TiN) and diamond-like carbon (DLC), can be applied to the mold surface to reduce friction, improve release properties, and prevent corrosion, further enhancing the performance and durability of the mold.

Choosing the Right Partner for Aluminum Alloy Die-Casting and Molds

Selecting the right partner for aluminum alloy die-casting and mold production is crucial for ensuring the success of your project. Here are some key factors to consider when choosing a die-casting manufacturer:

Experience and Expertise

Look for a manufacturer with a proven track record in aluminum alloy die-casting and die-casting mold design and production. An experienced manufacturer will have the technical know-how and expertise to handle complex projects and produce high-quality aluminum alloy castings and molds that meet your specific requirements.

Quality Assurance

Ensure that the manufacturer has a comprehensive quality control system in place, including in-process inspections and final product testing. Certification to international standards, such as ISO 9001, is a strong indicator of the manufacturer's commitment to quality.

Design Support

Choose a manufacturer that offers design support services, including CAD/CAM design and mold flow analysis. This will help you optimize your design for manufacturability, ensuring that your aluminum alloy die-castings can be produced efficiently and cost-effectively.

Production Capacity

Consider the manufacturer's production capacity and capabilities, including their ability to handle large-scale production runs and their capacity to meet your delivery deadlines. A manufacturer with a flexible production schedule and the ability to scale up or down production as needed will be better able to meet your changing requirements.

Customer Service

Finally, look for a manufacturer that offers excellent customer service and support. A responsive and reliable manufacturer will be able to address any issues or concerns that arise during the production process, ensuring a smooth and successful project.

Conclusion

Aluminum alloy die-casting and die-casting molds have revolutionized the modern manufacturing industry, enabling the production of complex, high-performance parts with exceptional precision, durability, and efficiency. From automotive components to aerospace structures, aluminum alloy castings and aluminum alloy die-castings have become the material of choice for countless applications, offering a unique combination of lightweight design, high strength, and corrosion resistance. With the continuous advancements in technology, such as 3D printing, smart manufacturing, and advanced mold materials, the future of aluminum alloy die-casting looks bright, promising even greater levels of precision, performance, and innovation. By choosing the right partner for your aluminum alloy die-casting and mold production needs, you can ensure the success of your project and stay ahead of the competition in today's rapidly evolving manufacturing landscape.

Get the latest price? We'll respond as soon as possible(within 12 hours)