2025 Die Casting Industry: Innovation, Global Expansion and Green Transition Drive Steady Growth Drive Steady Growth

2025-12-25 14:56

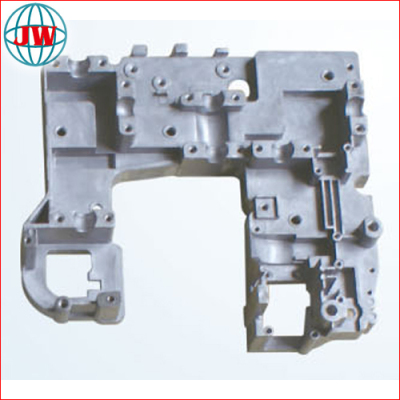

The global die casting industryis stepping into a new phase of high-quality development in 2025, with Integrated Die Casting leading technological innovation, emerging markets boosting regional growth, and Sustainable Manufacturing becoming a core competitive edge. As an indispensable manufacturing process for high-precision, lightweight components, die casting plays a pivotal role in supporting the upgrading of automotive, aerospace, consumer electronics and new energy industries. According to the latest data from Grand View Research, the global die casting market scale is expected to hit $185.6 billion by 2025, with a year-on-year growth of 11.2%, driven by the surging EV Component Demand and wide application of advanced alloy materials.

Integrated Die Casting: Rewriting the Rules of Component Production

Integrated Die Casting has become the most influential technological breakthrough in the die casting industry in 2025, fundamentally changing the traditional multi-part assembly mode. By using ultra-high-tonnage die casting machines (12,000 tons and above), this technology can integrally cast large and complex structural components such as EV chassis, battery packs and aerospace fuselage parts, which significantly reduces welding processes, shortens production cycles and improves component reliability.

Tesla’s 17,000-ton Giga Press 4.0 has officially entered mass production, realizing one-piece casting of EV rear floor assemblies and reducing component count by 80%. Major automakers around the world are accelerating the layout of this technology: BYD has built 8 integrated die casting bases in China, with an annual production capacity of 5 million one-piece chassis; Volkswagen has invested $3 billion to cooperate with LK Technology to develop 15,000-ton die casting machines, aiming to apply them to its electric vehicle models in 2026. In the aerospace field, Airbus uses Integrated Die Casting to produce lightweight components for eVTOL vehicles, reducing the weight of parts by 35% and improving flight endurance.

Global Market Pattern: Asia-Pacific Leads, Emerging Markets Rise

The Asia-Pacific region remains the core market of the global die casting industry, accounting for 65% of the total market share in 2025. China, as the world’s largest die casting producer and consumer, holds a 48% market share, supported by the mature EV industry chain, strong policy support and huge production capacity. Chinese die casting enterprises such as Guangdong Hongtu and Ningbo Huaxiang have continuously upgraded their technologies, focusing on high-value-added products such as precision die castings for luxury EVs and aerospace components, with exports increasing by 30% year-on-year.

India and Southeast Asia have become the fastest-growing emerging markets. Driven by the "Make in India" policy and the rapid development of the local automotive industry, India’s die casting market is growing at a CAGR of 15%, with Tata Motors and Hyundai building local die casting factories. Vietnam and Thailand, relying on low labor costs and superior geographical location, have attracted a large number of foreign investments, becoming important die casting production bases in Southeast Asia.

Europe and North America focus on the development of High-Precision Die Casting for high-end fields. Europe is a leader in aerospace and medical die casting components, with companies such as Nemak specializing in the production of complex parts made of titanium alloy and magnesium alloy. North America has promoted the resurgence of the local die casting industry through the Inflation Reduction Act, encouraging enterprises to carry out localized production of EV components and reducing dependence on imported products.

Green Transition: Circular Economy Becomes the Main Trend

Sustainable Manufacturing has become an inevitable choice for the die casting industry in 2025, as global environmental regulations become increasingly strict and consumers pay more attention to low-carbon products. The industry has comprehensively promoted the Circular Economy model, focusing on energy conservation, emission reduction and resource recycling.

Aluminum recycling has achieved remarkable results. The global recycling rate of die casting aluminum has reached 98%, and recycled aluminum accounts for 80% of the raw materials used in the die casting industry, which can reduce carbon emissions by 96% compared with primary aluminum. Many enterprises have introduced on-site scrap recycling systems, converting production waste into high-quality recycled aluminum ingots, realizing resource reuse. In addition, Eco-Friendly Melting Processes such as renewable energy-powered induction furnaces are widely used, reducing energy consumption by 48% compared with traditional melting processes.

Major die casting enterprises have set clear green development goals: Buhler Group plans to achieve carbon neutrality in all production bases by 2035; Guangdong Hongtu has completed the transformation of 100% renewable energy power supply in its factories, becoming a benchmark for green die casting enterprises.

Challenges and Future Outlook

Despite the strong growth momentum, the die casting industry still faces some challenges, such as the volatility of aluminum and magnesium raw material prices, the shortage of skilled talents in advanced technologies, and the high cost of green transformation.

Looking forward, the die casting industry will usher in more development opportunities. Low-Pressure Die Casting (LPDC) will be more widely used in high-precision component production; Additive Manufacturing for Die Molds will reduce mold production cycle by 70%; the integration of AI and Machine Learning will realize intelligent optimization of production processes and improve production efficiency.

In summary, 2025 is a key year for the transformation and upgrading of the die casting industry. Integrated Die Casting will continue to lead technological progress, the global market pattern will be further optimized, and green transformation will become the core driving force for development. Enterprises that seize the opportunities of technological innovation and green development will gain more competitive advantages in the future market competition.

Get the latest price? We'll respond as soon as possible(within 12 hours)