Aluminum Die-Casting Molds: The Unsung Architects of Precision Manufacturing

2025-08-15 15:30

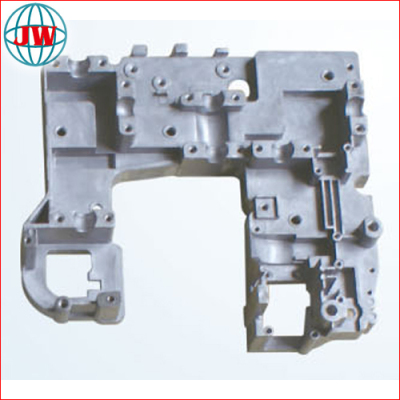

Behind every high-quality aluminum die-casting—from automotive engine parts to aerospace components—lies a critical yet often overlooked component: the aluminum die-casting mold. These precision-engineered tools are the backbone of modern manufacturing, enabling the mass production of complex, consistent aluminum parts that power industries worldwide. As demand for lightweight, durable aluminum components surges, die-casting molds are evolving to meet tighter tolerances, faster production cycles, and more ambitious design challenges.

The Role of Molds in Aluminum Die-Casting

Aluminum die-casting molds are specialized tools that shape molten aluminum into finished parts. Made from high-grade steel, these molds consist of two halves—the fixed “cover” and movable “ejector” plates—that form a cavity mirroring the desired part’s shape. During production, molten aluminum (heated to 650–700°C) is injected into this cavity under extreme pressure (up to 15,000 psi), filling every detail before cooling and solidifying.

The mold’s design directly impacts the quality of the final die-casting. A well-engineered mold ensures uniform metal flow, prevents air bubbles (which cause weaknesses), and allows for easy ejection of the cooled part. This precision is why molds are often called the “blueprint” of die-casting: even minor flaws in the mold—such as uneven surface finishes or misaligned cavities—can render thousands of parts defective.

Materials and Engineering: Building Molds for Durability

Aluminum die-casting molds must withstand extreme conditions: high temperatures, repeated pressure cycles, and corrosive molten aluminum. To meet these demands, manufacturers use specialized tool steels such as H13 (a chromium-molybdenum-vanadium alloy) and P20 (a pre-hardened steel), chosen for their heat resistance, wear resistance, and machinability.

H13 steel is particularly popular, as it retains its hardness (up to 50 HRC) at temperatures exceeding 500°C, ensuring the mold maintains its shape over 100,000+ production cycles. After forging, molds undergo rigorous heat treatment—including quenching and tempering—to enhance their toughness and prevent cracking. Surface treatments like nitriding further boost wear resistance, extending mold lifespans by 30–50% in high-volume production.

Technological Innovations in Mold Design

Advancements in design and manufacturing are revolutionizing aluminum die-casting molds. 3D modeling software (such as AutoCAD and SolidWorks) allows engineers to simulate metal flow, cooling, and ejection, identifying potential issues—like trapped air or uneven cooling—before the mold is built. This virtual testing reduces prototyping time by up to 60% compared to traditional methods.

Additive manufacturing (3D printing) is another game-changer. 3D-printed mold inserts with complex internal cooling channels—impossible to machine traditionally—enable faster, more uniform cooling of molten aluminum. This cuts cycle times by 20–30% and reduces thermal stress on the mold, extending its life. For example, a 3D-printed insert for an automotive bracket mold can cool the part in 8 seconds instead of 12, boosting production output by 500 units per day.

Customization for Diverse Industries

Aluminum die-casting molds are tailored to the unique needs of different sectors:

Automotive: Molds for EV battery enclosures require large, seamless cavities to prevent leaks, with integrated cooling channels to handle high-volume production (up to 10,000 parts daily).

Aerospace: Molds for aircraft components demand ultra-tight tolerances (±0.01mm) to ensure parts meet safety standards, often using H13 steel treated for maximum precision.

Consumer Electronics: Smaller molds for smartphone frames or laptop hinges prioritize intricate details, such as thin walls (0.5–1mm) and smooth surfaces, requiring high-precision machining.

Market Growth and Sustainability

The global aluminum die-casting mold market, valued at $4.2 billion in 2023, is projected to grow at 6.8% annually through 2030. This growth is driven by the rise of electric vehicles, renewable energy equipment, and smart manufacturing, all of which rely on high-quality aluminum parts.

Sustainability is also shaping the industry. Molds designed for longer lifespans reduce waste, while recycled steel content in mold production cuts carbon footprints. Additionally, energy-efficient cooling systems in modern molds lower overall production energy use by 15–20%.

Challenges and Future Trends

Despite their importance, aluminum die-casting molds face challenges, including rising steel costs and the need for faster turnaround times. To address these, manufacturers are adopting AI-driven predictive maintenance—using sensors to monitor mold wear and predict failures before they occur.

Looking ahead, 3D printing will play a larger role in mold production, enabling on-demand, low-volume molds for custom parts. Nanocoatings may further enhance mold durability, while digital twins (virtual replicas of molds) will allow real-time performance optimization.

Conclusion

Aluminum die-casting molds are the unsung heroes of precision manufacturing, enabling the production of the aluminum parts that drive innovation across industries. As technology advances, these molds will continue to evolve—becoming more durable, efficient, and customizable—ensuring that aluminum die-castings remain a cornerstone of modern manufacturing. In a world demanding lighter, stronger, and more sustainable products, the importance of a well-crafted die-casting mold has never been clearer

Get the latest price? We'll respond as soon as possible(within 12 hours)