Sustainability & Precision: Zinc Die Casting Molds Drive Growth in Auto & Electronics

2025-11-13 15:30

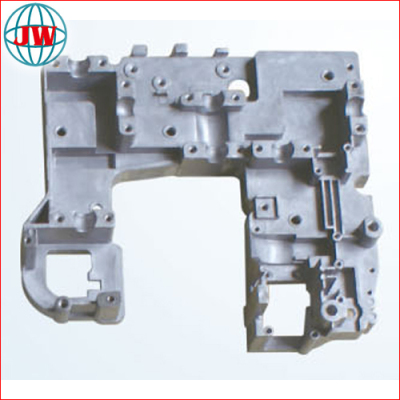

SEOUL, Nov. 10, 2025 – At a South Korean electronics manufacturing hub, a hot-chamber die-casting machine injects molten Zamak 5 alloy into a precision mold, producing a 46g EV connector shell in just 22 seconds. The finished part boasts a tolerance of ±0.03mm and passes a 48-hour salt spray test—meeting the strict standards of electric vehicle (EV) manufacturers. This scene highlights the rising prominence of zinc die casting and zinc die casting molds in high-growth sectors, as the global market for automotive zinc die cast parts alone is projected to expand at a CAGR of 3% through 2030, with Asia-Pacific leading as the largest market.

Sustainability has emerged as a core competitive advantage for zinc die casting. With a melting point of approximately 420°C—far lower than aluminum (660°C) or magnesium (650°C)—zinc requires up to 35% less energy during processing, significantly reducing carbon emissions. Zinc’s infinite recyclability further strengthens its eco-credentials: unlike many metals, it can be recycled repeatedly without quality degradation, supporting circular economy goals. Major automakers are already capitalizing on these benefits: BMW’s Leipzig plant reports a 28% reduction in unit energy consumption and 63% lower volatile organic compound emissions using zinc die casting comparedto traditional sand casting. To align with regulations like the EU’s ELV Directive, mold manufacturers are optimizing designs for minimal material waste, achieving raw material utilization rates of over 95%.

Material innovation is elevating the performance of zinc die cast components and molds. Advanced alloys like ZA-27 zinc-aluminum alloy now offer tensile strength exceeding 400MPa while maintaining a density of just 6.6g/cm³, enabling 35% weight reduction compared to traditional steel parts. German manufacturers have developed nano-enhanced zinc-based composites that boost fatigue strength by 40%, already adopted in chassis components for Audi’s e-tron series. Molds must keep pace with these high-performance alloys: modified H13 mold steel with specialized coatings now achieves a service life of over 150,000 cycles, a significant leap from conventional molds. For electronics, Zamak 5 alloy remains the gold standard, delivering excellent thermal conductivity and electromagnetic shielding—critical for 5G antenna brackets, smartphone midframes, and wireless charger coils.

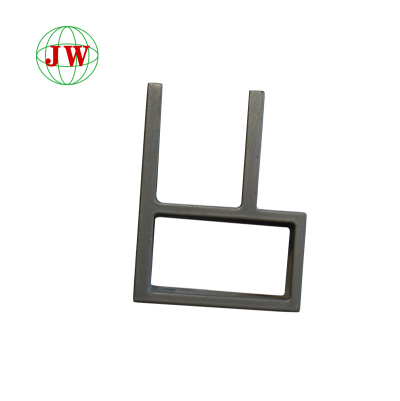

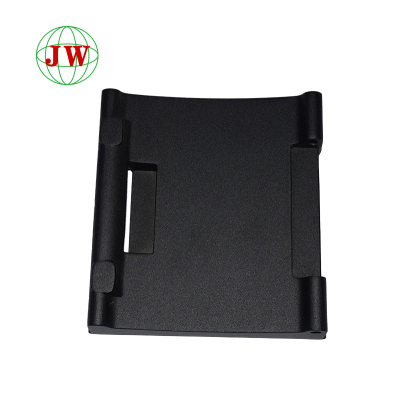

The EV and electronics sectors are the primary drivers of market growth, demanding precision and efficiency from molds. EV manufacturers rely on zinc die cast parts for battery connector shells, ADAS sensor brackets, and safety components like seatbelt buckles—all requiring molds that can replicate complex geometries with tight tolerances. Modern 8000-ton die-casting machines paired with intelligent mold temperature control systems have shortened cycle times for large parts (such as door inner panels) to just 90 seconds. In electronics, the trend toward miniaturization has pushed mold precision to new heights: molds now produce thin-walled components with surface roughness as low as Ra 0.8μm, eliminating the need for additional finishing processes. These advancements translate to tangible cost savings—automakers report a 22% reduction in comprehensive costs and 40% fewer assembly steps compared to traditional stamping and welding.

Intelligent mold technology is transforming production reliability. Leading molds are integrated with IoT sensors that monitor temperature, pressure, and wear in real time, transmitting data to cloud-based analytics platforms. This allows predictive maintenance, reducing unplanned downtime by 30% and ensuring consistent part quality. For complex EV components, digital twin technology simulates mold performance before physical production, optimizing cooling channel design and slashing development time by 25%. Additionally, 3D-printed mold inserts are gaining traction, enabling intricate internal structures that enhance alloy flow and reduce defect rates to below 0.5%. These smart features are particularly valuable for high-volume production, where even minor deviations can impact thousands of parts.

Despite strong growth, the industry faces challenges. Volatility in raw material prices and a global shortage of skilled mold designers (estimated at 28%) have constrained expansion for some manufacturers. However, solutions are emerging: increased adoption of recycled zinc feedstock stabilizes material costs, while industry-academia partnerships in Europe and Asia are training 15,000+ technicians annually in smart mold operation. Furthermore, advancements in vacuum die casting molds have addressed porosity issues, achieving porosity levels below 0.1% for critical aerospace and medical components.

As the industry looks to 2030, the synergy between sustainability, material innovation, and intelligent molds will define success. “Zinc die casting molds that combine eco-friendly design, precision engineering, and real-time data capabilities are becoming indispensable for high-tech manufacturing,” notes a senior analyst at Mordor Intelligence. With EV adoption accelerating and electronics demand soaring, the zinc die casting mold sector is poised for steady growth—proving that zinc’s unique balance of performance, efficiency, and sustainability is reshaping the future of manufacturing.

Get the latest price? We'll respond as soon as possible(within 12 hours)