Aluminum Alloy Furniture Connectors: Die-Casting Technology Revitalizes Home Furnishing Industry

2026-01-28 15:32

The global home furnishing industry is witnessing a technological upgrade driven by aluminum alloy die-casting components. As core accessories linking furniture structures, aluminum die-casting connectors are reshaping the industry with their superior precision, durability, and lightweight performance. Driven by the trends of flat-pack e-commerce furniture, smart home integration, and green consumption, the market demand for high-quality aluminum alloy furniture fittings is soaring. According to industry statistics, the global market size of aluminum die-casting furniture connectors is expected to reach $9.2 billion, with a steady year-on-year growth of 8.3%, and aluminum alloy products account for over 78% of the total market share due to their cost-effectiveness and sustainability <superscript:4.

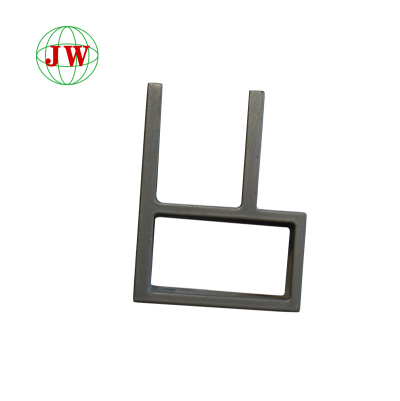

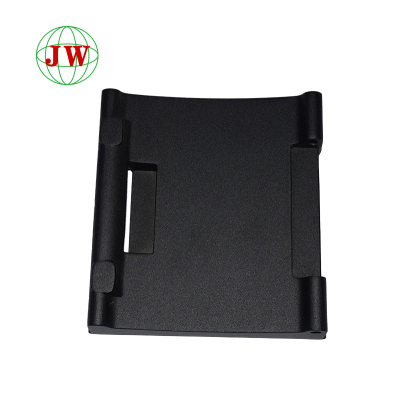

Technological innovation in die-casting is the core driver of product upgrading. High-pressure die-casting technology has become the mainstream production method for aluminum alloy furniture connectors, enabling one-piece molding of complex structures with dimensional tolerance controlled within ±0.1mm, which reduces assembly time by 30% compared to traditional split parts <superscript:2. Leading enterprises such as Yongzhu Casting have introduced 2,000-ton high-pressure die-casting presses, realizing mass production of integrated connectors with integrated bosses and alignment ribs, eliminating the need for secondary welding and improving structural stability <superscript:2. Vacuum die-casting technology is widely applied to high-end products, reducing surface bubbles and flow marks, and achieving mirror-smooth blanks that can be directly coated without secondary polishing <superscript:3.

Material optimization enhances the comprehensive performance of aluminum alloy die-casting connectors. ADC12 aluminum alloy remains the preferred material for furniture fittings, boasting excellent die-casting fluidity and mechanical strength, and can withstand 50,000-cycle abrasion tests after anodizing or powder coating <superscript:2. Recycled aluminum alloy applications are accelerating, with the utilization rate having risen from 35% in recent years to 48% currently, reducing carbon emissions per unit product by about 60% while maintaining product performance <superscript:1. Enterprises are also developing low-lead and cadmium-free environmental protection alloys to meet strict EU and North American environmental standards, expanding export channels for aluminum alloy furniture fittings<superscript:1.

The integration of aesthetics and functionality has become a new competitive focus. Modern furniture design pursues the unity of style and practicality, prompting aluminum die-casting connectors to break away from pure functionality. Through precision surface treatment processes such as anodizing, powder spraying, and wire drawing, manufacturers create a variety of textures and colors that match different furniture styles, from minimalist matte black to luxurious champagne gold <superscript:3. Xiongsheng Hardware, a domestic leader, achieves color consistency with ΔE < 1.0 by adopting Pantone standard color matching, ensuring uniform finishes across mass-produced components <superscript:2. Customized die-casting solutions are also popular, allowing manufacturers to tailor connector structures for sofas, tables, and cabinets, balancing easy assembly with load-bearing capacity <superscript:3.

The global market pattern shows obvious regional characteristics, with Asia-Pacific as the core supply hub. Chinese enterprises, relying on mature die-casting technology and cost advantages, occupy 45% of the global market share, with products exported to Europe, America, and Southeast Asia <superscript:4. Yongzhu Casting, with an annual capacity of 4,000 tons, has become a key supplier for international furniture brands, providingaluminum die-casting sofa frame brackets and table connectors that support up to 200kg and have a shear strength of ≥1,500N <superscript:4. The European market demands high environmental protection and durability, driving enterprises to obtain ASI certification and meet CBAM carbon footprint requirements, while the North American market favors cost-effective flat-pack furniture connectors <superscript:1.

Sustainability and intelligence are reshaping the industry’s development direction. Die-casting enterprises are accelerating the construction of green production lines, adopting electric induction melting furnaces and waste heat recovery systems to reduce unit energy consumption by 15%-20% <superscript:1. Intelligent manufacturing is deepening, with MES systems and optical detection equipment widely used to achieve real-time monitoring of the die-casting process and a 99.2% product qualification rate <superscript:3. The industry concentration is further improving, with top 10 enterprises accounting for 40% of the market share, while small and medium-sized enterprises are focusing on niche markets such as micro aluminum alloy die-casting components <superscript:1.

Looking ahead, the aluminum alloy die-casting furniture connector industry will focus on precision improvement, green innovation, and global layout. With the deep integration of lightweight design and sustainable development concepts, die-casting technology will continue to break through, making connectors more integrated, aesthetic, and environmentally friendly. Enterprises that grasp the trends of material innovation and intelligent production will gain a competitive edge, driving the global furniture industry towards high-quality development

Get the latest price? We'll respond as soon as possible(within 12 hours)