What are castings in machining?

2025-06-13 16:42

In the realm of manufacturing and machining, castings play a fundamental role as versatile and cost-effective components that serve as the building blocks for countless products across diverse industries. Castings refer to parts or objects formed by pouring molten material, typically metal, into a pre-designed mold cavity and allowing it to solidify. Once cooled, the solidified piece, known as a casting, is ejected from the mold, often requiring additional machining operations to achieve the final desired shape, dimensions, and surface finish. This article delves into the key aspects of castings in machining, exploring their types, processes, advantages, and applications.

At its core, the concept of castings revolves around the transformation of a fluid state material into a solid object with a specific geometry. Metals are the most commonly used materials for castings due to their strength, durability, and wide range of mechanical properties. However, other materials such as ceramics, polymers, and even glass can also be cast. The process begins with the creation of a mold, which can be made from various materials like sand, metal, or ceramic, depending on the casting method employed.

The molten material is then carefully poured into the mold cavity, filling it completely. As it cools and solidifies, the material takes on the shape of the mold. Once solid, the casting may have excess material, rough surfaces, or dimensional inaccuracies. This is where machining comes into play. Machining operations, such as cutting, milling, turning, and grinding, are used to remove the excess material, refine the dimensions, and improve the surface finish of the casting, transforming it into a functional component ready for assembly.

There are several casting processes used in machining, each with its own unique characteristics and applications:

Sand Casting

Sand casting is one of the oldest and most widely used casting methods. In this process, a pattern, which is a replica of the desired casting, is used to create a mold cavity in a sand mixture. The sand mold is typically made up of two halves, known as the cope and the drag. Molten metal is poured into the cavity, and once it solidifies, the sand mold is broken away to reveal the casting. Sand casting is highly versatile, allowing for the production of large and complex castings in various metals. It is often used for low to medium production volumes and is cost-effective for prototypes and custom parts.

Die Casting

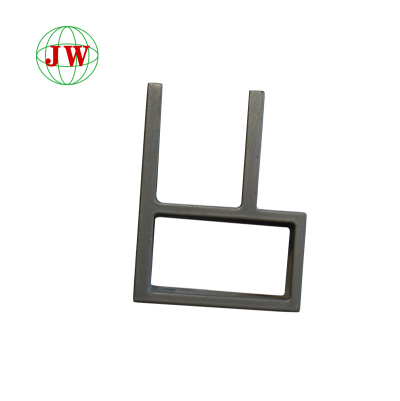

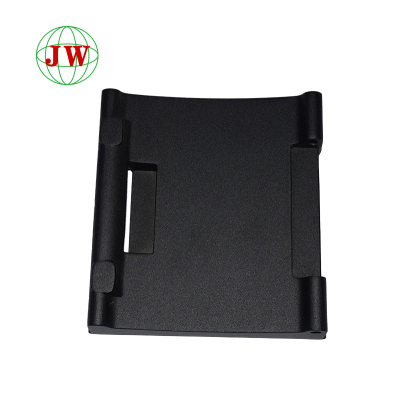

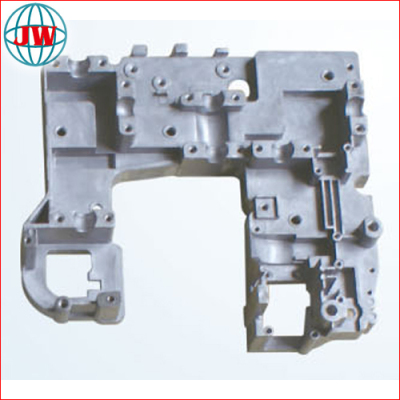

Die casting involves injecting molten metal under high pressure into a reusable metal mold, known as a die. The die is typically made of hardened steel and consists of two halves that come together to form the mold cavity. This process offers high precision, excellent surface finish, and the ability to produce castings with intricate details and thin walls. Die castings are commonly made from non-ferrous metals such as aluminum, zinc, and magnesium alloys. It is well-suited for high-volume production, making it popular in industries like automotive, consumer electronics, and aerospace.

Investment Casting

Also known as lost-wax casting, investment casting starts with creating a wax pattern of the desired casting. The wax pattern is then coated with a ceramic shell, which is allowed to dry and harden. The wax is melted out, leaving behind a hollow ceramic mold. Molten metal is poured into the mold, filling the cavity. Once the metal solidifies, the ceramic shell is broken away, revealing the casting. Investment casting is capable of producing highly detailed and accurate castings with complex geometries, making it ideal for applications where precision is crucial, such as in the jewelry, medical, and aerospace industries.

Advantages of Castings in Machining

Castings offer numerous advantages that make them a preferred choice in machining and manufacturing:

Design Flexibility

One of the key benefits of castings is their ability to accommodate complex shapes and geometries that may be difficult or impossible to achieve through other manufacturing methods. Casting processes allow for the integration of features such as internal cavities, thin walls, and intricate details directly into the casting, reducing the need for additional assembly or machining operations.

Cost-Effectiveness

For high-volume production, casting can be a cost-effective solution. Once the mold is created, the production of multiple castings can be achieved relatively quickly and with minimal additional tooling costs. Additionally, casting can make efficient use of materials, reducing waste compared to some other manufacturing processes like machining from solid stock.

Material Versatility

Castings can be produced from a wide range of materials, including various metals, alloys, polymers, and ceramics. This allows manufacturers to select the material that best suits the specific requirements of the application, such as strength, corrosion resistance, heat tolerance, or electrical conductivity.

Applications of Castings in Machining

The versatility of castings makes them indispensable in numerous industries:

Automotive Industry

In the automotive sector, castings are used extensively for engine components, transmission parts, suspension components, and body panels. Aluminum alloy die castings are particularly popular for engine blocks and cylinder heads due to their lightweight and high strength, contributing to improved fuel efficiency. Sand castings may be used for larger, less complex parts such as brake drums and intake manifolds.

Aerospace Industry

Aerospace applications demand components with high strength-to-weight ratios and exceptional reliability. Investment castings are commonly used to produce critical parts like turbine blades, engine casings, and structural components. These castings are often made from high-performance alloys such as titanium and nickel-based alloys, which can withstand extreme temperatures and mechanical stresses.

Consumer Goods

In the production of consumer goods, castings are found in a variety of products, from kitchen appliances and power tools to furniture and decorative items. Zinc alloy die castings are frequently used for small, intricate parts due to their good surface finish and ease of casting, while aluminum castings may be used for larger components that require strength and durability.

In conclusion, castings are a vital element in machining, offering a combination of design flexibility, cost-effectiveness, and material versatility. Understanding the different casting processes, their advantages, and applications is essential for manufacturers to select the most appropriate method for producing high-quality components that meet the demands of modern industries.

Get the latest price? We'll respond as soon as possible(within 12 hours)