Are you looking for medical casting suppliers who can meet customized needs?

2024-10-12 16:40

In the field of medical technology, precision and customization are of utmost importance. Medical casting plays a crucial role in the production of various medical devices and components. Whether it's for surgical instruments, orthopedic implants, or diagnostic equipment, finding reliable medical casting suppliers who can meet customized needs is essential.

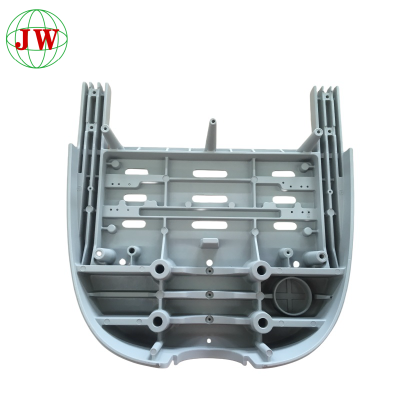

Die Casting is a manufacturing process that involves forcing molten metal under high pressure into a mold cavity. This process is widely used in the production of medical casting due to its ability to produce complex shapes with high precision and repeatability. However, not all medical casting suppliers are created equal. When looking for a supplier, it's important to consider several factors to ensure that they can meet your specific requirements.

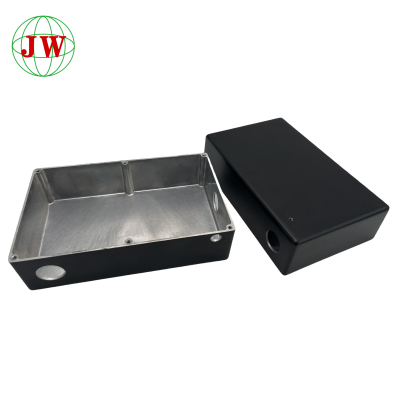

One of the key factors to consider is the supplier's experience and expertise in medical casting. Look for a supplier who has a proven track record of producing high-quality medical casting products. They should have experience working with different materials, such as stainless steel, titanium, and cobalt-chromium alloys, and be familiar with the specific requirements and regulations of the medical industry.

Another important factor is the supplier's ability to provide customized solutions. Every medical device or component has unique requirements, and a good medical casting supplier should be able to work closely with you to understand your needs and develop a customized solution. This may involve designing and manufacturing a specific mold, using specialized materials, or implementing unique finishing processes.

The supplier's quality control processes are also crucial. In the medical industry, quality is non-negotiable. Look for a supplier who has a comprehensive quality control system in place, including incoming material inspection, in-process quality control, and final inspection. They should also be able to provide documentation and certifications to ensure that their products meet the required standards.

In addition to quality, delivery time is also an important consideration. Medical devices often have tight production schedules, and a delay in the delivery of medical casting components can have a significant impact on the overall project. Look for a supplier who can provide reliable delivery times and has a good track record of meeting deadlines.

Technology and innovation are also important factors to consider. The medical field is constantly evolving, and a good medical casting supplier should be able to keep up with the latest technological advancements. Look for a supplier who invests in research and development and uses state-of-the-art equipment and processes to ensure the highest quality products.

Finally, customer service is essential. A good medical casting supplier should be responsive, communicative, and committed to meeting your needs. They should be able to answer your questions promptly, provide updates on your orders, and address any concerns or issues that may arise.

In conclusion, finding reliable medical casting suppliers who can meet customized needs is crucial for the success of your medical device or component project. Consider the factors mentioned above when evaluating potential suppliers to ensure that you choose a partner who can provide high-quality products, customized solutions, reliable delivery times, and excellent customer service. With the right supplier, you can be confident that your medical casting needs will be met, and your project will be a success.

Related News

More >-

![Aluminum Die-Cast Building Accessories: Innovation and Sustainability Reshape Construction Sector]()

Aluminum Die-Cast Building Accessories: Innovation and Sustainability Reshape Construction Sector

Aluminum die-cast accessories drive the construction industry’s upgrade, with die-cast building accessories favored for light weight and durability. Advanced die-casting tech and recycled materials boost sustainability. Asia-Pacific leads the market, with smart buildings fueling demand for high-performance, multi-functional aluminum die-cast products.

-

![2025 Furniture Die-Casting Connectors: Precision, Aesthetics and Global Demand Drive Industry Upgrade]()

2025 Furniture Die-Casting Connectors: Precision, Aesthetics and Global Demand Drive Industry Upgrade

In 2025, the global furniture die-casting connector industry grows steadily, driven by smart home demand and advanced die casting tech. Zinc/aluminum alloys are mainstream, with intelligent die casting equipment and die casting mold upgrades boosting precision and efficiency. Aesthetics, customization and sustainability become key focuses. Asia-Pacific leads supply-demand, Chinese enterprises excel globally via quality and cost advantages, fueling high-end, sustainable development.

-

![Aluminum Die-Casting Industry Thrives: Powering New Energy, Advanced Manufacturing, and Sustainable Production]()

Aluminum Die-Casting Industry Thrives: Powering New Energy, Advanced Manufacturing, and Sustainable Production

The aluminum die-casting industry is a manufacturing linchpin, valued at 42Bin2024andprojectedtohit 65B by 2030 (7.6% CAGR). NEVs drive demand most—aluminum’s lightness aids battery range, with Tesla’s Giga Press and firms like BYD using large-format aluminum die-casting for parts (e.g., battery housings). Alloys like AA6061 are key, and NEVs made up 52% of 2023’s demand. It also expands into renewables (solar brackets, wind casings) and advances via Vacuum Die-Casting and AI control. While aluminum price volatility and high machine costs challenge, NEV charging infrastructure and policy support offer opportunities.

-

![Aluminum Die-Cast Parts & Molds: Symbiotic Innovation Drives Automotive, Renewable, and Tech Sectors]()

Aluminum Die-Cast Parts & Molds: Symbiotic Innovation Drives Automotive, Renewable, and Tech Sectors

The aluminum die-casting industry, a manufacturing core, was valued at 42Bin2024andisprojectedtoreach 65B by 2030 (7.6% CAGR). NEVs are its top driver—aluminum’s lightness boosts battery range. Tesla’s Giga Press and BYD use large-format aluminum die-casting for parts like battery housings, with NEVs accounting for 52% of 2023’s demand (key alloy: AA6061). It also expands into renewables (solar brackets, wind casings) and advances via Vacuum Die-Casting and AI control. Challenges include aluminum price volatility and high machine costs, but NEV charging infrastructure and policy support bring opportunities.

-

![Aluminum Building Die-Castings: Reshaping Modern Construction with Strength and Sustainability]()

Aluminum Building Die-Castings: Reshaping Modern Construction with Strength and Sustainability

Aluminum building die-castings are transforming construction, merging strength, versatility, and sustainability. Lighter and more corrosion-resistant than steel or concrete, they enable durable, efficient components like curtain wall brackets and structural connectors. Die-casting with alloys such as 6061/A356 creates complex, precise parts (±0.03mm tolerance) with 290 MPa tensile strength, aiding modular builds. Using up to 80% recycled aluminum cuts energy use by 95%, aligning with green standards. The $7.3B 2023 market grows 6.9% yearly, driven by urbanization and modular trends. Innovations like smart sensors and 3D-printed molds will further their role in modern, eco-friendly architecture.

-

![Aluminum Alloy Die-Cast Connectors: The Unsung Heroes Shaping Modern Furniture Stability]()

Aluminum Alloy Die-Cast Connectors: The Unsung Heroes Shaping Modern Furniture Stability

Aluminum alloy die-cast connectors, vital for modern furniture, offer precision and durability via advanced die-casting and molds. These H13 steel-molded components, strong (280 MPa) and corrosion-resistant, outperform traditional connectors. With 3D-designed molds enabling complex geometries and sustainability via recyclable aluminum, they drive modular furniture growth, set to thrive in smart, eco-friendly designs.

-

![Die Casting Molds: The Unsung Heroes Shaping Modern Manufacturing]()

Die Casting Molds: The Unsung Heroes Shaping Modern Manufacturing

Die casting molds are vital in manufacturing, enabling high-volume production of precise, durable parts. Made from robust materials like H13 steel, they withstand extreme temperatures and pressure, producing 100,000–1M+ parts. CAD, 3D printing, and AI enhance their design and longevity. Used in automotive (EV components), electronics, and aerospace, they drive cost efficiency and innovation. Challenges include high upfront costs and supply issues, but advancements in monitoring and sustainability boost their role, making them key to modern production.

-

![Die Castings and Die Casting Molds: The Backbone of High-Precision Manufacturing]()

Die Castings and Die Casting Molds: The Backbone of High-Precision Manufacturing

Die castings and die casting molds are vital in manufacturing, forming durable, precise parts. Molds offer repeatability (100,000–1M cycles), design flexibility, and long-term cost efficiency. Die castings boast strength, lightness (aluminum 30% lighter than steel), dimensional accuracy (50% less machining vs. sand casting), and material efficiency. Used in automotive, electronics, and machinery, they face mold maintenance challenges but benefit from 3D-printed inserts, AI design, and sustainability trends, ensuring their key role in future production.

Get the latest price? We'll respond as soon as possible(within 12 hours)