Looking for manufacturers who can provide customized communication component die-casting solutions?

2024-10-15 15:00

In the rapidly evolving field of communication technology, the demand for high-quality and customized communication component die-casting solutions is on the rise. As the backbone of modern communication systems, communication components play a crucial role in ensuring seamless connectivity and efficient signal transmission. Die Casting, a manufacturing process known for its precision and efficiency, offers a viable option for producing complex and durable communication components.

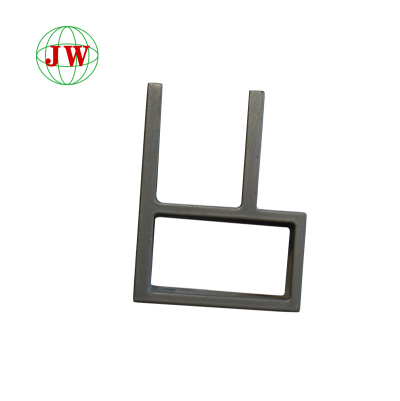

Communication component die-casting involves the use of molten metal, typically aluminum or zinc alloys, which is injected under high pressure into a mold cavity. This process allows for the creation of intricate shapes with tight tolerances, making it ideal for manufacturing communication components such as connectors, housings, and heat sinks. The resulting parts are not only strong and durable but also offer excellent electrical conductivity and thermal management properties.

One of the key advantages of communication component die-casting is its ability to provide customized solutions. Manufacturers can design and produce molds that are tailored to the specific requirements of different communication components, ensuring a perfect fit and optimal performance. This level of customization is essential in an industry where every component needs to be precisely engineered to meet the unique demands of different communication systems.

For example, a manufacturer may be required to produce a custom housing for a specific communication device. The housing needs to be designed to fit the dimensions and specifications of the device precisely, while also providing adequate protection against environmental factors such as dust, moisture, and impact. Communication component die-casting allows for the creation of such custom housings with ease, as the mold can be designed to incorporate features such as gaskets, ventilation slots, and mounting points.

Another important aspect of communication component die-casting is the quality of the materials used. High-quality aluminum and zinc alloys are commonly used in the die-casting process due to their excellent mechanical properties, electrical conductivity, and corrosion resistance. Manufacturers need to source these materials from reliable suppliers and ensure that they meet the strict quality standards required for communication components.

In addition to material quality, the manufacturing process itself also needs to be carefully controlled to ensure consistent quality and performance. This includes factors such as injection pressure, temperature, and cycle time, which can all affect the final properties of the die-cast parts. Manufacturers who specialize in communication component die-casting have the expertise and equipment to optimize these process parameters and ensure that every part produced meets the highest quality standards.

Furthermore, manufacturers who can provide comprehensive communication component die-casting solutions often offer additional services such as design engineering, prototyping, and post-processing. Design engineering services can help customers optimize their component designs for die-casting, ensuring that the parts are not only functional but also cost-effective to produce. Prototyping allows customers to test and validate their designs before committing to full-scale production, reducing the risk of costly mistakes. Post-processing services such as machining, polishing, and plating can be used to enhance the appearance and performance of the die-cast parts, further adding value to the final product.

When looking for manufacturers who can provide customized communication component die-casting solutions, it is important to consider several factors. Firstly, the manufacturer's experience and expertise in the field of communication component manufacturing is crucial. Look for a manufacturer who has a proven track record of producing high-quality die-cast parts for communication applications and who understands the unique requirements of the industry.

Secondly, the manufacturer's capabilities in terms of design engineering, prototyping, and post-processing should be evaluated. A manufacturer who can offer a full range of services can provide a one-stop solution for customers, saving time and reducing costs.

Thirdly, the quality control measures implemented by the manufacturer should be examined. Look for a manufacturer who has a comprehensive quality management system in place and who conducts regular inspections and tests to ensure that every part produced meets the required quality standards.

Finally, the manufacturer's reputation and customer service should be considered. Read reviews and testimonials from previous customers to get an idea of the manufacturer's reliability and responsiveness. A manufacturer who is committed to providing excellent customer service can help ensure a smooth and successful project.

In conclusion, the demand for customized communication component die-casting solutions is growing as the communication technology industry continues to evolve. Manufacturers who can offer high-quality, customized solutions, along with comprehensive services and strict quality control, are well-positioned to meet the needs of this dynamic market. By carefully evaluating potential manufacturers based on their experience, capabilities, quality control, and customer service, customers can find the right partner to provide the communication component die-casting solutions they need to succeed in their communication projects.

Related News

More >-

![Aluminum Alloy Furniture Connectors: Die-Casting Technology Revitalizes Home Furnishing Industry]()

Aluminum Alloy Furniture Connectors: Die-Casting Technology Revitalizes Home Furnishing Industry

Aluminum alloy die-casting connectors drive the home furnishing industry upgrade, favored for precision, durability and light weight. High-pressure and vacuum die-casting tech, plus material optimization, boost product performance. Asia-Pacific leads supply, with sustainability and intelligence shaping trends, pushingaluminum die-casting fittings toward high-end development..

-

![2025 Aluminum Alloy Furniture Die Castings: Green Materials and Design Innovation Drive Market Transformation]()

2025 Aluminum Alloy Furniture Die Castings: Green Materials and Design Innovation Drive Market Transformation

In 2025, the global aluminum alloy furniture die casting industry is transforming, driven by sustainable furniture demand, outdoor/smart home popularity and precision casting breakthroughs. Valued at $38.6 billion (6.2% CAGR 2023-2025), it relies on recycled aluminum (28% global adoption) for low-carbon goals. Key techs like precision sand casting, vacuum die casting and digital twin boost performance and design. Outdoor furniture contributes 45% of demand, with medical segment growing fastest (18.3%). Asia-Pacific leads (35% share), while Europe and North America have steady growth. Despite price volatility and trade barriers, the industry will trend green, precise and modular, with recycled aluminum use to exceed 40% by 2030.

-

![2025 Die Casting Industry: Innovation, Global Expansion and Green Transition Drive Steady Growth Drive Steady Growth]()

2025 Die Casting Industry: Innovation, Global Expansion and Green Transition Drive Steady Growth Drive Steady Growth

In 2025, the global die casting industry enters a high-quality development phase, driven by Integrated Die Casting, Sustainable Manufacturing and surging EV Component Demand, with the market expected to reach $185.6 billion (11.2% YoY growth). Asia-Pacific dominates (65% share) led by China, while India and Southeast Asia emerge. Europe and North America focus on High-Precision Die Casting. Key trends include wide application of integrated casting, Circular Economy practices (98% aluminum recycling) and Eco-Friendly Melting Processes. Despite challenges like raw material volatility, Low-Pressure Die Casting (LPDC), Additive Manufacturing for Die Molds and AI integration will fuel future growth.

-

![Sustainability & Precision: Zinc Die Casting Molds Drive Growth in Auto & Electronics]()

Sustainability & Precision: Zinc Die Casting Molds Drive Growth in Auto & Electronics

As of Nov. 2025, zinc die casting molds are thriving in EV and electronics sectors, with the global automotive zinc die cast parts market projected to grow at a 3% CAGR through 2030 (Asia-Pacific leading). Zinc’s low melting point (420°C) cuts energy use by 35% and enables infinite recyclability, aligning with sustainability goals. Advanced alloys like ZA-27 and Zamak 5 enhance performance, while modified H13 steel molds and smart tech (IoT sensors, digital twins, 3D-printed inserts) boost precision, reliability, and efficiency. Despite raw material price volatility and skilled labor shortages, recycled feedstock and training partnerships offer solutions. These molds, balancing eco-friendliness and tight tolerances, are becoming indispensable for high-tech manufacturing.

-

![Global Die-Casting Sector Sees Surge in Demand for EV Components, Fueled by Tech Advancements and Regional Expansion]()

Global Die-Casting Sector Sees Surge in Demand for EV Components, Fueled by Tech Advancements and Regional Expansion

The global die-casting industry hits $82B in 2024, projected to reach $125B by 2030 (7.3% CAGR), driven by EV demand, tech advances, and emerging market expansion. Large-format die-casting leads EV manufacturing—Ningbo Haitian’s 12,000-ton machine makes full-size EV underbodies, while LG partners on lighter aluminum battery enclosures. Smart die-casting systems (IoT, AI) cut defects by 45% (Bühler) and speed inspections (Megvii’s AI scans 500 parts/hour). India (via “National Die-Casting Mission”) and Southeast Asia attract investments (Hyundai Mobis’ Vietnam plant). Sustainability efforts include closed-loop recycling (BMW) and low-carbon production (Haldex’s renewable-powered plant), despite challenges like high machine costs and skilled labor gaps.

-

![Global Die-Casting Industry Surges: Driven by EV Demand, Material Innovation, and Sustainable Practices]()

Global Die-Casting Industry Surges: Driven by EV Demand, Material Innovation, and Sustainable Practices

The global die-casting industry is growing rapidly, valued at $78B in 2024 and projected to hit $115B by 2030 (6.8% CAGR). EV demand is the top driver—High-Pressure Die-Casting (HPDC) makes large parts like EV battery housings, with Tesla’s Giga Press inspiring rivals like Ford. Material innovation, such as lightweight magnesium alloys and recycled metals, cuts weight and emissions. Industry 4.0 tech boosts efficiency: digital twins reduce mold development time by 25%, IoT-enabled molds lower downtime, and AI inspects 100% of parts. Despite challenges (high machinery costs, skilled labor gaps), the industry remains key to sustainable mobility and manufacturing.

-

![Global Die-Casting Industry Booms: Aluminum Die-Castings and Die-Casting Molds Drive EV-Driven Growth in 2025]()

Global Die-Casting Industry Booms: Aluminum Die-Castings and Die-Casting Molds Drive EV-Driven Growth in 2025

In 2025, the global die-casting industry thrives, driven by aluminum die-castings demand (especially in EVs) and advanced die-casting molds. The sector is projected to reach $88.03 billion in 2025, with EVs using 250kg aluminum die-castings per vehicle on average (e.g., Tesla’s Model Y). Die-casting molds innovate via ceramic-coated steel (80,000+ cycles) and AI (cutting design time to days). Sustainability gains include 70% of firms using mold remanufacturing; China mandates 100% mold waste recycling by 2025. By 2030, the industry may hit $119.14 billion, with Giga Casting 2.0 and AI fueling growth, key for EV/aerospace sectors.

-

![Aluminum Die-Casting Molds: The Unsung Architects of Precision Manufacturing]()

Aluminum Die-Casting Molds: The Unsung Architects of Precision Manufacturing

Aluminum die-casting molds are vital yet underrecognized for high-quality aluminum die-castings (auto, aerospace parts). Made of H13/P20 steel, they use 650–700°C molten aluminum injected at 15,000 psi, with design ensuring uniform flow and part quality. 3D modeling and 3D printing (e.g., cooling inserts cutting cycle time 20–30%) innovate molds. Tailored to industries—auto needs EV battery molds, aerospace requires ±0.01mm tolerance—they drive the $4.2B 2023 market (6.8% annual growth to 2030). Facing steel cost hikes, AI maintenance and future nanocoatings/digital twins will boost their durability and efficiency.

Get the latest price? We'll respond as soon as possible(within 12 hours)