Powering Efficiency and Reliability: The Unmatched Advantages of Aluminum Alloy Die-Cast Motor End Caps

2025-06-10 15:43

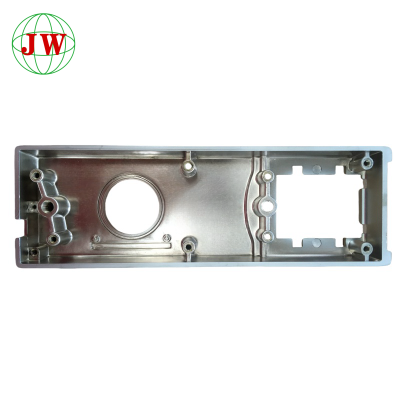

In the ever-evolving landscape of electrical machinery manufacturing, the demand for components that combine lightweight design, superior thermal management, and robust durability has never been higher. Aluminum alloy motor end caps, crafted through the precision of die-casting molds, have emerged as a game-changing solution for electric motor applications across industries. These aluminum alloy die-cast componentsnot only enhance the performance and lifespan of motors but also streamline production processes, making them an essential choice for modern manufacturing. This comprehensive article delves into the features, benefits, and applications of, highlighting their pivotal role in driving innovation in the electrical industry.

The Die-Casting Process: Precision Engineering for Motor End Caps

At the core of every high-quality aluminum alloy motor end cap lies a meticulously engineered die-casting mold. The die-casting process involves injecting molten aluminum alloy under high pressure into a mold cavity, which is designed to the exact specifications of the end cap. Once the metal solidifies, the mold is opened, and the finished aluminum alloy die-cast component is ejected, ready for assembly.

The Role of Die-Casting Molds

Die-casting molds are the key to achieving consistent quality and precision in the production of motor end caps. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are used to create molds with intricate geometries and tight tolerances. These molds are typically made from high-grade tool steel, ensuring they can withstand the extreme pressures and temperatures of the die-casting process. A well-designed mold not only guarantees the dimensional accuracy of the end cap but also enables the integration of complex features, such as mounting holes, cooling fins, and internal ribs, without additional machining.

Material Advantages of Aluminum Alloys

Aluminum alloys are the preferred choice for motor end caps due to their unique combination of properties:

Lightweight Design: Aluminum alloys offer an excellent strength-to-weight ratio, significantly reducing the overall weight of the motor. This is particularly beneficial for applications where weight reduction is crucial, such as in electric vehicles, aerospace, and portable machinery.

Superior Thermal Conductivity: With high thermal conductivity, aluminum alloy end caps efficiently dissipate heat generated by the motor, preventing overheating and extending the motor's lifespan. This property is essential for maintaining optimal performance, especially in high-load or continuous-operation scenarios.

Corrosion Resistance: Aluminum alloys naturally form a thin oxide layer on their surface, providing inherent corrosion resistance. This makes aluminum alloy motor end caps suitable for a wide range of environments, from humid industrial settings to outdoor applications.

Key Benefits of Aluminum Alloy Die-Cast Motor End Caps

Precision and Consistency

The die-casting process ensures that each aluminum alloy motor end cap is produced with exceptional precision, meeting strict dimensional tolerances. This consistency reduces assembly time and minimizes errors, as end caps fit perfectly with other motor components. The use of die-casting molds allows for the repeatable production of high-quality end caps, even in large volumes, ensuring uniform performance across multiple motors.

Design Flexibility

Aluminum alloy die-cast components offer unparalleled design flexibility, enabling manufacturers to create motor end caps with complex shapes and features. Whether it's integrating cooling channels, reinforcing ribs, or custom mounting interfaces, die-casting can accommodate a wide range of design requirements. This flexibility not only enhances the functionality of the end cap but also allows for optimization of the motor's overall performance.

Cost-Effectiveness

Despite the initial investment in die-casting molds, the production of aluminum alloy motor end caps through die-casting is highly cost-effective, especially for high-volume manufacturing. The process is highly automated, reducing labor costs and increasing production efficiency. Additionally, the precision of die-casting minimizes the need for post-processing operations, such as machining or finishing, further lowering production costs.

Durability and Longevity

Aluminum alloy end caps are highly durable, capable of withstanding mechanical stress, vibration, and thermal cycling. Their corrosion resistance ensures that they maintain their integrity over time, even in harsh operating conditions. This durability translates to a longer lifespan for the motor, reducing maintenance costs and downtime for end-users.

Applications of Aluminum Alloy Motor End Caps

Electric Vehicles (EVs)

In the rapidly growing EV market, aluminum alloy motor end caps play a crucial role in reducing the vehicle's weight and improving energy efficiency. Their lightweight design helps to extend the vehicle's range, while their excellent thermal management properties ensure the optimal performance of the electric motor. These end caps are also resistant to the vibrations and shocks experienced during vehicle operation, contributing to the overall reliability of the EV drivetrain.

Industrial Machinery

In industrial settings, motors are often subjected to heavy loads and continuous operation. Aluminum alloy motor end caps provide the necessary strength and heat dissipation capabilities to withstand these demanding conditions. Their corrosion resistance makes them suitable for use in factories, plants, and other industrial environments where exposure to moisture, chemicals, or dust is common.

Home Appliances

For home appliances such as washing machines, air conditioners, and fans, aluminum alloy motor end caps offer a combination of lightweight design and durability. Their precision manufacturing ensures quiet operation, while their corrosion resistance protects against the humidity and heat generated during appliance use.

Aerospace and Defense

In the aerospace and defense sectors, where reliability and weight reduction are critical, aluminum alloy end caps are the preferred choice for electric motors. Their high strength-to-weight ratio helps to minimize the weight of aircraft and military equipment, while their ability to withstand extreme temperatures and harsh environments ensures consistent performance in mission-critical applications.

Technological Advancements in Aluminum Alloy Die-Casting

3D Printing and Rapid Prototyping

The integration of 3D printing technology in die-casting mold development has significantly reduced the time and cost associated with producing prototypes. 3D-printed molds allow manufacturers to quickly test and refine the design of aluminum alloy motor end caps, accelerating the product development cycle. This technology enables rapid iterations, ensuring that the final product meets the highest standards of performance and quality.

Smart Manufacturing and Automation

Modern die-casting facilities are increasingly adopting smart manufacturing technologies, including robotics and artificial intelligence (AI). Automated die-casting machines equipped with sensors and AI algorithms can monitor and optimize the production process in real-time. This not only improves the efficiency and consistency of end cap production but also reduces the risk of human error, leading to higher-quality aluminum alloy die-cast components.

Advanced Alloy Formulations

Ongoing research in materials science has led to the development of new aluminum alloys with enhanced properties. These advanced alloys offer improved strength, thermal conductivity, and corrosion resistance, further enhancing the performance of aluminum alloy motor end caps. For example, new alloys with added silicon or magnesium content can provide better heat dissipation and mechanical strength, making them ideal for high-performance motor applications.

Choosing the Right Supplier for Aluminum Alloy Motor End Caps

Selecting a reliable supplier is crucial for ensuring the quality and performance of aluminum alloy motor end caps:

Experience and Expertise: Look for a supplier with a proven track record in producing aluminum alloy die-cast components, especially motor end caps. A supplier with extensive experience will have the technical know-how to handle complex designs and material requirements.

Quality Assurance: Ensure that the supplier has a comprehensive quality control system in place, including in-process inspections and final product testing. Certification to international standards, such as ISO 9001, is a strong indicator of their commitment to quality.

Design Support: A good supplier should offer design assistance, helping to optimize the end cap design for manufacturability and performance. Their expertise in CAD/CAM design and die-casting technology can significantly enhance the efficiency of the production process.

Sustainability Practices: In today's environmentally conscious market, choose a supplier that prioritizes sustainable manufacturing practices, such as recycling scrap aluminum and reducing energy consumption during production.

Conclusion

Aluminum alloy motor end caps, produced through the precision of die-casting molds, are essential components for modern electric motors. Their unique combination of lightweight design, superior thermal management, and robust durability makes them indispensable across a wide range of industries. As technology continues to advance, the capabilities of aluminum alloy die-cast components will only improve, driving further innovation in the electrical machinery sector. By partnering with a trusted supplier, manufacturers can harness the full potential of these end caps, ensuring the reliability, efficiency, and longevity of their electric motor products. Whether in electric vehicles, industrial machinery, or consumer appliances, aluminum alloy motor end caps are powering the future of electrical engineering

Get the latest price? We'll respond as soon as possible(within 12 hours)