Aluminum Die-Castings: Powering Innovation Across Industries with Precision and Versatility

2025-08-14 17:14

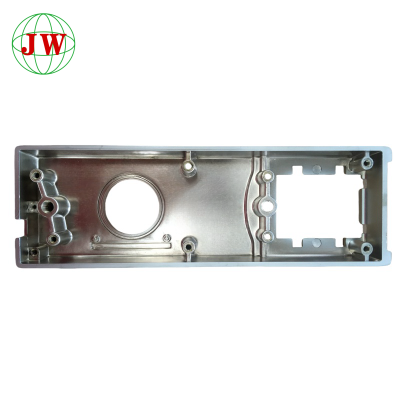

In today’s manufacturing landscape, aluminum die-castings have become indispensable, driving progress in sectors ranging from automotive and aerospace to construction and consumer electronics. These metal components, produced through the high-pressure die-casting process, combine exceptional strength, lightweight properties, and design flexibility, making them a cornerstone of modern industrial innovation.

The Science Behind Aluminum Die-Castings

At the heart of aluminum die-castings lies a sophisticated manufacturing process that transforms molten aluminum alloy into complex, high-precision parts. The process begins with melting aluminum alloys—commonly ADC12, A380, or 6061, chosen for their fluidity and mechanical properties—at temperatures between 650–700°C. This molten metal is then injected under extreme pressure (up to 15,000 psi) into steel molds engineered with intricate details, from tiny threads to hollow cavities.

The high pressure ensures the metal fills every crevice of the mold, resulting in die-castingswith tight tolerances (often ±0.02mm) and smooth surfaces. Once cooled, the part is ejected, requiring minimal post-processing—unlike machining or forging, which often leave rough edges. This efficiency makes aluminum die-casting ideal for mass production, with a single mold capable of producing hundreds of thousands of consistent parts.

Key Advantages of Aluminum Die-Castings

Aluminum die-castings offer a unique set of benefits that set them apart from other manufacturing methods and materials:

Strength-to-Weight Ratio: Aluminum’s natural lightness (one-third the density of steel) combined with the structural integrity imparted by die-castingresults in parts that are both strong and lightweight. This is critical for industries like automotive and aerospace, where reducing weight improves fuel efficiency and performance.

Corrosion Resistance: Aluminum forms a protective oxide layer, making die-castings resistant to rust and degradation—even in harsh environments. This durability extends the lifespan of products, from outdoor machinery to marine equipment.

Design Freedom: The die-casting processallows for complex geometries that would be impossible with traditional methods. Engineers can integrate multiple features—such as mounting points, channels, and internal ribs—into a single part, reducing assembly time and costs.

Cost-Effectiveness: High production speeds and minimal waste make aluminum die-castingseconomically viable for large-scale manufacturing. Recyclability adds to their value: aluminum can be melted and reused indefinitely, cutting raw material costs and supporting sustainability goals.

Applications Across Industries

Aluminum die-castings are ubiquitous in daily life, though their presence often goes unnoticed. In the automotive sector, they form transmission housings, engine brackets, and EV battery enclosures, contributing to lighter, more energy-efficient vehicles. Tesla’s use of giant die-cast underbodies, for example, reduces the number of parts in a car by 70%, streamlining production.

In aerospace, aluminum die-castings are used in aircraft interiors and structural components, where their lightweight strength reduces fuel consumption. The construction industry relies on them for curtain wall brackets and window frames, as seen in skyscrapers like Dubai’s Burj Khalifa, where they support glass facades while withstanding high winds.

Even consumer electronics benefit: die-cast aluminum frames protect smartphonesand laptops, balancing durability with sleek design. Power tools, medical devices, and household appliances also use these components for their reliability and precision.

Innovations Driving the Industry Forward

Advancements in die-casting technology are expanding the capabilities of aluminum die-castings. Mega-casting machines, capable of producing parts weighing over 100kg, are revolutionizing automotive manufacturing by creating large, integrated components. 3D printing is transforming mold design, allowing rapid prototyping and customization—reducing development time from months to weeks.

Smart die-casting systems, equipped with sensors and AI, monitor pressure, temperature, and flow in real time, minimizing defects and ensuring consistent quality. Meanwhile, new aluminum alloys, such as those reinforced with carbon fiber, are pushing the limits of strength and heat resistance, opening doors to applications in high-performance industries.

Market Growth and Sustainability

The global aluminum die-castings market, valued at $78 billion in 2023, is projected to grow at 7.5% annually through 2030. This growth is fueled by the rise of electric vehicles, renewable energy infrastructure, and smart manufacturing.

Sustainability is a key driver: 95% of the energy used to produce primary aluminum is saved when recycling, and many manufacturers now use 50–80% recycled material in their die-castings. This aligns with global efforts to reduce carbon footprints, making aluminum die-castings a preferred choice for eco-conscious brands.

Conclusion

Aluminum die-castings are the unsung heroes of modern manufacturing, enabling innovation across industries with their unique blend of strength, precision, and sustainability. From cars to skyscrapers, and smartphones to aircraft, these components play a vital role in shaping the products and structures that define daily life. As technology advances, aluminum die-castings will continue to evolve, driving efficiency, reducing environmental impact, and powering the next generation of industrial breakthroughs.

Get the latest price? We'll respond as soon as possible(within 12 hours)