Aluminum Furniture Die Castings: How Molds and Components Shape Modern Design

2025-07-29 16:01

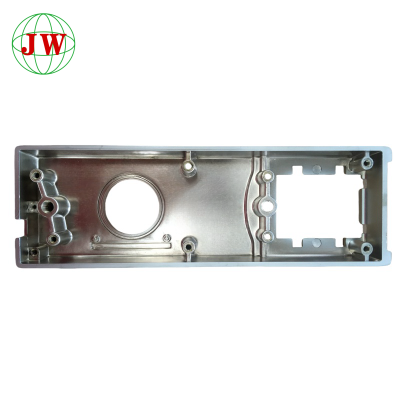

In the evolving world of furniture manufacturing, aluminum die castings have become synonymous with durability, precision, and innovation. At the heart of this transformation lie two critical elements: die casting molds and the high-quality die castings they produce. Together, they are redefining how aluminum furniture is designed, produced, and experienced—from sleek outdoor patio sets to minimalist indoor seating.

The Role of Die Casting Molds: Precision in Every Detail

Die casting molds are the unsung heroes behind aluminum furniture’s rise. Crafted from hardened steel (often H13 or P20 alloys), these molds are engineered to withstand extreme temperatures (up to 700°C) and intense pressure (1,000–20,000 psi) during the casting process. Their design directly dictates the quality, consistency, and complexity of the final aluminum die castings.

Modern molds are developed using 3D modeling and computer-aided design (CAD) software, allowing manufacturers to create intricate geometries—think curved chair legs, hollow table frames, or interlocking modular components—that would be costly or impossible with traditional woodworking or welding. For example, a mold for a lightweight aluminum patio chair can integrate thin-walled supports (as thin as 1.5mm) with reinforcing ribs, balancing strength and weight.

What sets these molds apart is their repeatability. A single die casting mold can produce 50,000–100,000 identical castings before needing maintenance, ensuring uniformity across furniture lines. This consistency is critical for brands: a set of dining chairs with die cast aluminum legswill all stand at the exact same height, with identical finishes, eliminating the mismatches common in handcrafted furniture.

Aluminum Die Castings: Strength Meets Versatility

Aluminum die castings themselves are revolutionizing furniture design. The process involves injecting molten aluminum alloy (typically ADC12 or A380, chosen for their strength and fluidity) into molds under high pressure, resulting in parts with:

· Superior Strength: Aluminum die castings have a tensile strength of 200–300 MPa, making them strong enough to support heavy tabletops or withstand the weight of daily use in commercial settings like cafes or offices.

· Lightweight: At 2.7 g/cm³, aluminum is 30% lighter than steel, making furniture easier to move and reducing shipping costs.

· Corrosion Resistance: Unlike iron or steel, aluminum forms a natural oxide layer that resists rust—ideal for outdoor furniture exposed to rain or humidity.

Take outdoor lounge sets: Die cast aluminum armrests and frame joints replace rust-prone steel, lasting 10+ years without peeling or warping. Indoor pieces, such as minimalist bookshelves, use die cast aluminum brackets to support heavy loads while maintaining a sleek, unobtrusive look.

Molds and Castings: Driving Efficiency and Sustainability

The partnership between die casting molds and castings is reshaping manufacturing efficiency. Traditional furniture production often involves cutting, welding, and finishing multiple parts—labor-intensive steps with high material waste. In contrast, die casting produces near-net-shape parts, reducing the need for post-processing. A mold for a chair base can integrate 6 legs and a central hub in one casting, eliminating 10+ welding points.

This efficiency aligns with the furniture industry’s push for sustainability. Aluminum die castings are 100% recyclable, and manufacturers increasingly use recycled aluminum (up to 70% in some alloys) to reduce carbon footprints. Molds also contribute: their long lifespan minimizes waste, and modern mold design software optimizes material usage, cutting aluminum scrap by 25% compared to 2010.

Innovations in Mold Design and Casting Technology

Advancements in die casting molds are unlocking new possibilities. 3D-printed mold inserts allow for rapid prototyping, letting designers test chair leg geometries or table joint designs in weeks instead of months. For example, Italian brand B&B Italia used 3D-printed molds to prototype a die cast aluminum lounge chair with a organic, wave-like frame—achieving a design once thought unmanufacturable.

Smart molds are another breakthrough. Equipped with sensors, they monitor temperature and pressure during casting, adjusting in real time to prevent defects like porosity (tiny air bubbles). This ensures castings for high-end furniture, such as luxury dining sets, meet strict quality standards.

On the casting side, new alloys like Al-Si-Mg-Cu (6061 grade) enhance strength, allowing thinner walls for more delicate designs. Powder coating, applied to die cast parts, adds color and texture—from matte black to metallic bronze—without compromising durability.

Market Growth: A Trend Fueled by Demand

Demand for aluminum die cast furniture is booming. The global aluminum furniture market, valued at $8.2 billion in 2023, is projected to grow 5.8% annually through 2030, driven by urbanization and a preference for low-maintenance, modern designs. Brands like Herman Miller and IKEA now feature die cast aluminum pieces in their flagship lines, highlighting "durability" and "sustainability" as key selling points.

This growth benefits mold makers too. Companies like RJG Inc. report a 40% increase in orders for aluminum furniture molds since 2020, with clients seeking larger, more complex designs—such as die cast aluminum sofa frames with integrated USB ports.

Challenges and the Road Ahead

Despite progress, challenges remain. High upfront costs for molds (ranging from $50,000 to $200,000 for complex designs) can deter small manufacturers. However, this is offset by lower per-unit costs for high-volume production.

Looking ahead, 3D printing may further disrupt the sector. Printing molds from high-performance ceramics could reduce lead times, while 3D-printed die cast parts may enable fully customized furniture—think chairs with castings tailored to a user’s body shape.

In the end, aluminum die casting molds and castings are more than manufacturing tools: they’re enablers of design freedom, durability, and sustainability. As consumers and brands prioritize long-lasting, eco-friendly furniture, their role in shaping the industry’s future has never been clearer.

Get the latest price? We'll respond as soon as possible(within 12 hours)