Die-Casting Industry’s Dual Breakthroughs: Surging Demand for Die-Cast Components Drives Die-Casting Mold Innovation

2025-09-04 16:52

The global die-casting industry is embracing a dual dividend era of "demand explosion" and "technological iteration" in 2025. As lightweight demands surge in sectors like new energy vehicles (NEVs) and medical devices, the market size of die-cast components is expected to exceed $320 billion. Meanwhile, die-casting molds—the core production equipment—are achieving leapfrog development empowered by technologies such as AI and new materials, forming an industrial pattern where "downstream demand drives upstream innovation."

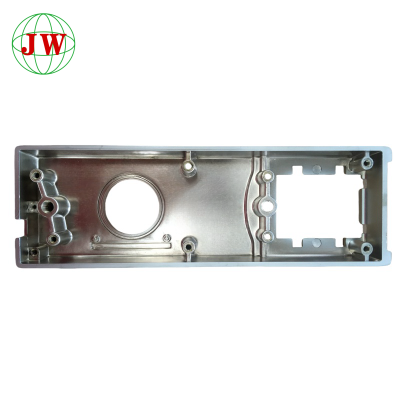

The explosive growth in demand for die-cast components is primarily fueled by the NEV industry. Data shows that in 2025, the per-vehicle usage of die-cast components in global NEVs has reached over 50kg, triple that of traditional fuel vehicles. Taking Tesla’s Model Y as an example, its integrated die-castrear floor die-cast component integrates 70 traditional parts into one, reducing weight by 30% and increasing production efficiency by 40%. This trend of "replacing welding with casting" has directly driven the upgrade of die-casting molds toward larger sizes and higher precision. At the 2025 Global Die-Casting Conference, LK Group launched the GIGA CASTING 2.0 technology, introducing a 9,000-ton extra-large die-casting machine with supporting molds. These molds enable integrated molding of entire vehicle chassis, with mold cavity dimensional error controlled within ±0.03mm, meeting the precision manufacturing requirements of extra-large die-cast components.

Technological innovation in die-casting molds is breaking through along two key dimensions: "materials" and "intelligence." In the material field, traditional H13 tool steel can no longer meet the high-temperature resistance needs of extra-large die-cast components. In 2025, new ceramic-coated mold steel emerged, extending mold service life to over 80,000 cycles—an increase of 60% compared to traditional steel. It can also withstand the impact of molten aluminum at temperatures above 700°C, effectively solving mold wear issues in integrated die-casting. The "Digital Mold Center" in Baden-Württemberg, Germany, has further developed carbon fiber-reinforced resin-based composite molds, which are 40% lighter than steel molds. This provides a new solution for manufacturing lightweight die-cast components in the aerospace sector and has received support from Germany’s Industry 4.0 special fund.

The in-depth penetration of artificial intelligence is reshaping the design and production processes of die-casting molds. Dongguan E-An Technology has built an AI intelligent design system that completely transforms the traditional model relying on Senior craftsman’s experience. After inputting basic parameters of die-cast components, the system can automatically generate 3-5 sets of mold schemes based on over a decade of historical data. Through simulation optimization of cooling channel layouts, it shortens the mold development cycle from 2 months to less than 3 days. The company’s simultaneously developed 3D intelligent retrieval system uses image recognition technology to enable "search by image" for molds, increasing the reuse rate of old mold designs by 50% and significantly reducing R&D costs. This "AI + mold" model has become the core competitiveness of Chinese die-casting mold enterprises in seizing the global market.

The concept of green manufacturing is also reshaping the die-casting mold industry ecosystem. In 2025, 70% of global die-casting mold enterprises have adopted mold remanufacturing technology, using laser cladding to repair worn cavities and reducing mold scrap rates by 35%. Small and medium-sized enterprises in Germany, supported by the ZIM Innovation Fund, have developed mold waste heat recovery systems that convert heat released by molds during die-casting into electricity, saving 12,000 kWh of electricity per mold annually. China, on the policy front, is promoting the full-life-cycle management of die-casting molds, requiring large-scale enterprises to achieve 100% recycling of mold waste by the end of 2025, further driving the industry toward low-carbon transformation.

Looking ahead, the collaborative innovation between die-cast components and die-casting molds will become even closer. With the popularization of GIGA CASTING 2.0 technology, the global market size of integrated die-cast components is expected to exceed $80 billion by 2030, driving annual demand growth of 25% for extra-large die-casting molds. Pang Dong, R&D director at E-An Technology, notes: "The next generation of die-casting molds will realize full-process intelligence in ‘design-production-maintenance.’ AI will not only optimize mold structures but also monitor mold temperature and pressure in real time through sensors to predict maintenance cycles." This "intelligence + green" development path will propel the die-casting industry to become a key engine for the transformation and upgrading of the manufacturing sector

Get the latest price? We'll respond as soon as possible(within 12 hours)