Die Casting: A Catalyst for Innovation in the Lighting Industry

2025-05-28 15:00

In recent years, die casting has emerged as a game-changer in the lighting industry, revolutionizing the way lighting fixtures are designed, manufactured, and delivered. This advanced manufacturing technique, which involves injecting molten metal under high pressure into a mold cavity, is enabling the production of high-quality, durable, and aesthetically pleasing lighting components that meet the evolving needs of modern consumers.

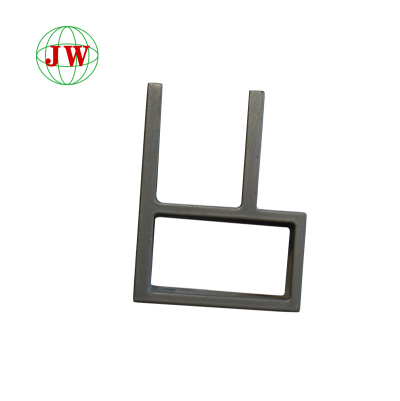

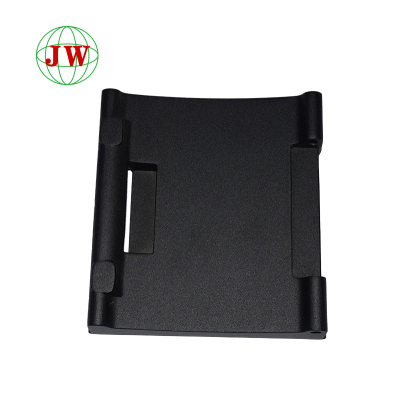

One of the primary advantages of die casting in the lighting sector is its ability to create complex geometries with exceptional precision. Lighting designers are no longer limited by traditional manufacturing constraints; instead, they can bring their most imaginative concepts to life. From intricate chandelier frames to sleek, minimalist LED light housings, die casting allows for the production of components with fine details, smooth surfaces, and tight tolerances. This level of precision ensures seamless assembly and enhances the overall functionality and visual appeal of lighting fixtures.

Material selection is another key aspect that makes die casting ideal for lighting applications. Aluminum alloys are particularly popular due to their lightweight yet robust properties. They offer excellent thermal conductivity, which is crucial for efficient heat dissipation in LED lighting systems. By effectively managing heat, die-cast aluminum components help extend the lifespan of LEDs, maintain consistent light output, and prevent overheating, thereby improving the reliability and performance of the entire lighting fixture. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor use, ensuring that lighting products can withstand various environmental conditions.

Zinc alloys also play a significant role in die-cast lighting components. Known for their high strength and ability to replicate intricate designs, zinc alloys are often used for decorative elements such as lamp finials, sconce brackets, and ornamental details. These components not only add a touch of elegance and style to lighting fixturesbut also contribute to their structural integrity. The versatility of zinc alloys allows manufacturers to create both classic and contemporary designs, catering to a wide range of consumer preferences.

The production efficiency of die casting further contributes to its growing popularity in the lighting industry. Once the mold is created, the die-casting process can produce large quantities of identical components in a relatively short period. This mass-production capability reduces manufacturing costs and lead times, enabling lighting companies to meet market demands more effectively. Moreover, the automated nature of die casting minimizes human error, ensuring consistent quality across all products.

In addition to functional and economic benefits, die casting also aligns with the growing trend towards sustainability in the lighting industry. Many of the metals used in die casting, including aluminum and zinc, are highly recyclable. By incorporating recycled materials into the manufacturing process, lighting manufacturers can reduce their environmental impact and contribute to a circular economy. Additionally, the durability of die-cast components means that lighting fixtures last longer, reducing the frequency of replacements and ultimately conserving resources.

The applications of die-cast lighting components are vast and diverse. In the residential market, they are used to create ambient, task, and accent lighting solutions that enhance the comfort and aesthetics of homes. From pendant lights in dining rooms to wall sconces in hallways, die-cast fixtures add a touch of sophistication and warmth to living spaces. In the commercial and hospitality sectors, die-cast lightingis essential for creating inviting and functional environments. Hotels, restaurants, offices, and retail stores rely on high-quality lighting fixtures to attract customers, improve productivity, and enhance the overall ambiance.

Looking ahead, the future of die casting in the lighting industry is bright. As technology continues to advance, we can expect to see even more innovative applications of this manufacturing process. For example, the integration of smart lighting technologies, such as Internet of Things (IoT) sensors and wireless controls, into die-cast fixtures is becoming increasingly common. These smart features allow users to control the brightness, color, and scheduling of their lights remotely, providing greater convenience and energy savings.

Furthermore, the development of new materials and alloys, as well as advancements in die-casting equipment and techniques, will likely lead to the creation of lighter, stronger, and more energy-efficient lighting components. For instance, the use of magnesium alloys, which are even lighter than aluminum, could open up new possibilities for portable and flexible lighting solutions.

In conclusion, die casting has become an integral part of the modern lighting industry, driving innovation, quality, and sustainability. Its unique combination of precision, material versatility, production efficiency, and environmental friendliness makes it an indispensable manufacturing method for creating cutting-edge lighting fixtures. As the demand for high-performance, aesthetically pleasing, and eco-friendly lighting continues to grow, die casting will undoubtedly play an even more significant role in shaping the future of the industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)