The Evolution of Furniture Engineering: Aluminum Alloy Die-Cast Furniture Connectors

2025-06-27 16:59

In the competitive landscape of modern furniture manufacturing, aluminum alloy die-cast furniture connectors have emerged as the cornerstone of structural innovation. These precision components blend mechanical strength, design versatility, and manufacturing efficiency, redefining how furniture is assembled and experienced. Crafted through advanced die-casting processes using specialized die-casting molds, these connectors address the industry’s need for durable, lightweight, and aesthetically appealing solutions. This article explores the technical advantages, applications, and technological breakthroughs of aluminum alloy die-cast furniture connectors, highlighting their role in shaping the future of furniture engineering.

The Art of Aluminum Die-Casting for Furniture Connectors

Aluminum alloy die-casting is a manufacturing marvel that transforms molten aluminum into intricate aluminum alloy die-castings with micrometer-level precision. The process begins with a die-casting mold, typically machined from H13 tool steel, which serves as the blueprint for the connector’s geometry. Molten aluminum alloy is injected under 100-150 MPa pressure into the mold cavity, solidifying to form a connector that matches the design specifications flawlessly.

Material Science Behind Aluminum Connectors

Aluminum alloys used in die-casting (e.g., A380, ADC12) offer a unique blend of properties:

Lightweight Strength: With a density of 2.7 g/cm³, aluminum alloy die-cast furniture connectors are 60% lighter than steel counterparts while maintaining tensile strengths up to 320 MPa.

Corrosion Resistance: A natural oxide layer protects aluminum connectors from humidity, making them ideal for indoor and outdoor furniture.

Thermal Stability: Aluminum’s high thermal conductivity (150 W/m·K) prevents heat buildup in electronic furniture applications.

The Role of Die-Casting Molds

Die-casting molds are the backbone of precision production. Modern molds incorporate:

Multi-slide Core Structures: For complex features like undercuts in connector interfaces.

Cooling Channels: Engineered to control solidification and minimize internal stresses.

Surface Texturing: To replicate finishes like brushed metal or anti-slip patterns directly in the casting.

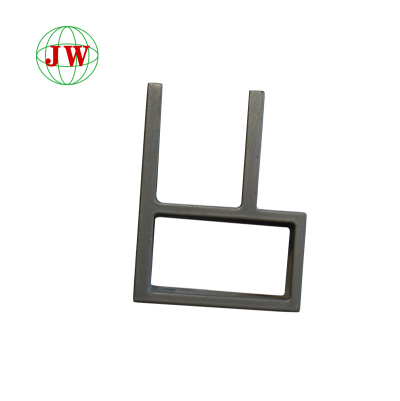

Figure 1: A multi-cavity die-casting mold for aluminum furniture connectors, showcasing integrated cooling channels.

Core Advantages of Aluminum Alloy Die-Cast Furniture Connectors

Unmatched Dimensional Accuracy

The high-pressure die-casting process ensures aluminum alloy die-castings with tolerances as tight as ±0.05 mm. This precision eliminates the need for post-machining, reducing production costs by up to 30%. For example, a table leg connector can be cast with pre-threaded holes and mating surfaces that fit perfectly with minimal assembly adjustment.

Design Flexibility for Modern Aesthetics

Unlike traditional stamped or forged components, aluminum alloy die-cast furniture connectors enable:

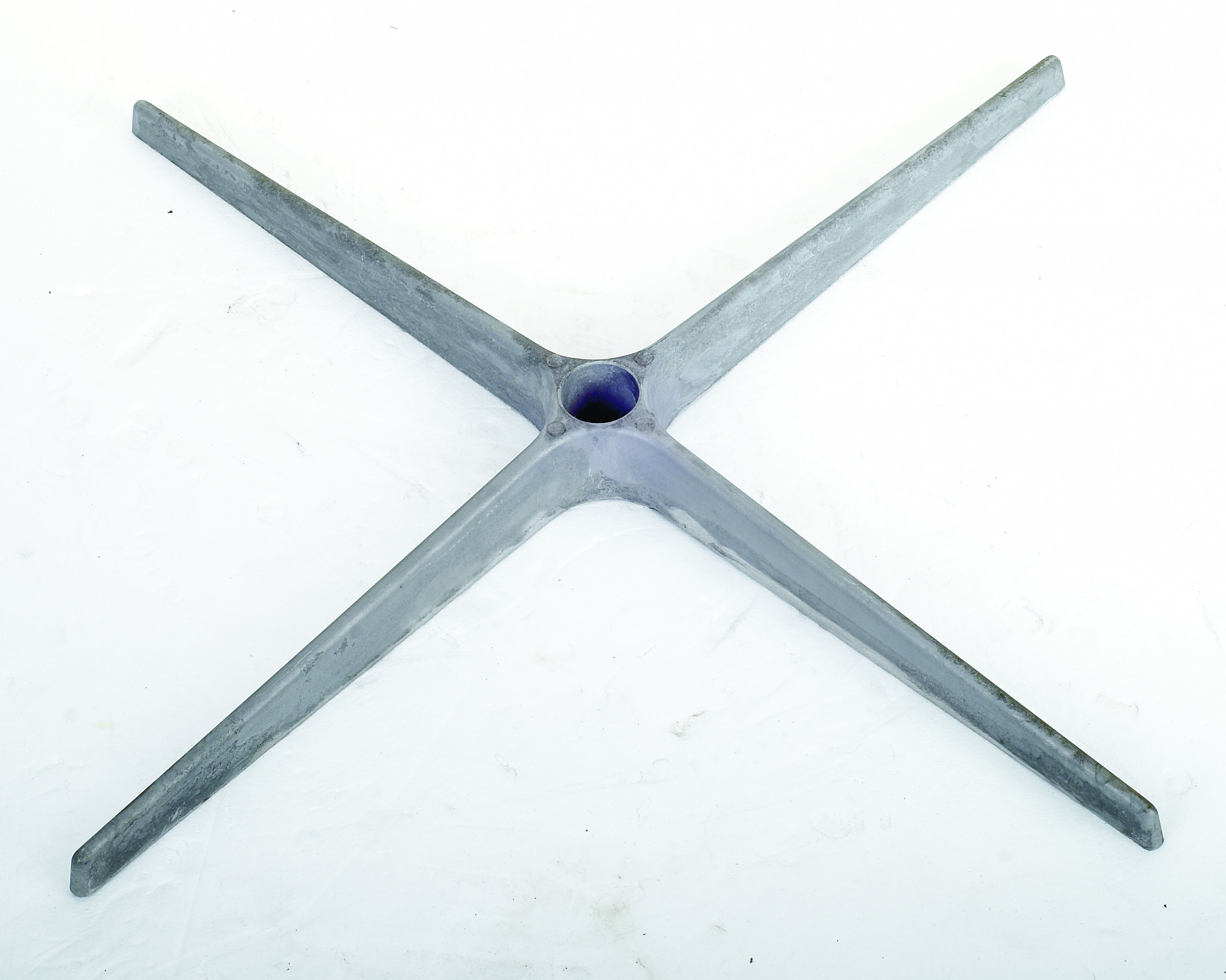

Organic Shapes: Curved profiles and asymmetrical designs impossible with sheet metal fabrication.

Integrated Functions: Features like snap-fit joints, cable channels, and mounting bosses can be cast in one piece.

Minimal Wall Thicknesses: Down to 1.5 mm, allowing lightweight yet rigid structures.

Cost-Effectiveness at Scale

While die-casting molds involve initial investment, high-volume production (10,000+ parts) drives per-unit costs down significantly. Automated casting cells can produce 500+ connectors per hour, with defect rates below 0.5% when using premium alloys.

Sustainable Manufacturing

Aluminum’s 95% recyclability makes aluminum alloy die-cast furniture connectors an eco-friendly choice. Post-consumer connectors can be remelted without losing mechanical properties, aligning with circular economy principles.

Applications Across Furniture Segments

Residential Furniture: Blending Form and Function

In homes, aluminum alloy die-cast furniture connectors excel in:

Modular Shelving Systems: Quick-connect brackets that allow easy reconfiguration.

Outdoor Furniture: Corrosion-resistant hinges and latches for patio sets.

Folding Furniture: Lightweight yet durable joints for collapsible tables and chairs.

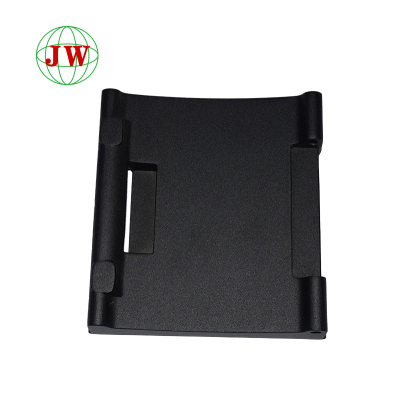

Figure 2: Aluminum die-cast connectors in a modular bookshelf system, demonstrating design versatility.

Commercial & Contract Furniture: Durability Under Pressure

Hotels, offices, and public spaces demand connectors that withstand heavy use:

Hotel Casegoods: Hidden connectors for cabinets that maintain aesthetic purity.

Office Partition Systems: Load-bearing brackets for height-adjustable desks.

Retail Displays: Custom connectors that enable quick assembly of promotional fixtures.

DIY & Flat-Pack Furniture: Empowering Creativity

Companies like IKEA leverage aluminum alloy die-cast furniture connectors for:

Tool-Free Assembly: Push-fit connectors that eliminate the need for screws.

Customization Kits: Interchangeable connectors allowing users to modify furniture designs.

Technological Innovations in Die-Casting

3D Printing for Rapid Mold Prototyping

Additive manufacturing has revolutionized die-casting mold development:

Rapid Tooling: 3D-printed aluminum molds can be produced in days, versus weeks for traditional machining.

Design Iteration: Engineers use 3D-printed mold prototypes to test flow dynamics and solidification patterns before committing to steel tools.

Smart Manufacturing Integration

Modern casting facilities employ:

AI-Powered Process Control: Sensors monitor injection pressure, temperature, and cycle time to optimize casting quality in real-time.

Robotic Post-Processing: Automated deburring and finishing cells ensure consistent surface quality.

Advanced Surface Finishing

Beyond basic powder coating, innovations include:

Physical Vapor Deposition (PVD): For premium metal finishes like brushed gold or chrome.

Nano-Coatings: Anti-microbial layers for healthcare furniture applications.

Figure 3: An automated production line for aluminum furniture connectors, featuring robotic handling and AI quality control.

Selecting the Right Die-Casting Partner

Choosing a manufacturer requires evaluating:

Material Expertise: Ability to recommend alloys (e.g., A356 for high-strength vs. A380 for complex geometries).

Mold Design Capability: Experience with multi-slide molds and conformal cooling.

Quality Assurance: ISO 9001 certification and in-house testing (tensile, salt spray, etc.).

Sustainability Practices: Recycling programs and energy-efficient casting processes.

A reliable partner will offer design-for-manufacturability (DFM) reviews, helping optimize connector designs to reduce material waste and production costs.

Conclusion: The Future of Furniture Connection Technology

Aluminum alloy die-cast furniture connectors have transcended mere functional components to become enablers of innovative furniture design. Their combination of lightweight strength, design flexibility, and cost-effectiveness positions them as the material of choice for next-generation furniture. As technology evolves—with advancements like 4D-printed molds and sustainable casting practices—these connectors will continue to redefine what’s possible in furniture engineering. For manufacturers and designers seeking to balance aesthetics, durability, and sustainability, aluminum alloy die-cast furniture connectors represent the pinnacle of modern manufacturing excellence.

Get the latest price? We'll respond as soon as possible(within 12 hours)