Aluminum Motorcycle Die-Casting Parts: Lightweight Innovation Drives Industry Upgrade

2026-01-29 15:30

The global motorcycle industry is undergoing a lightweight transformation fueled by aluminum motorcycle die-casting parts, with aluminum components becoming the core of performance optimization. Driven by the rising demand for electric motorcycles, enhanced riding control, and environmental protection policies, motorcycle die-casting accessories have evolved from auxiliary parts to key elements determining vehicle safety and efficiency. Aluminum die-casting technology, paired with high-performance aluminum alloys, balances light weight, strength, and corrosion resistance, making aluminum components indispensable in motorcycle manufacturing. Industry data shows the global market for aluminum motorcycle die-casting parts is expanding steadily, with electric motorcycles and customized models emerging as major growth drivers <superscript:1.

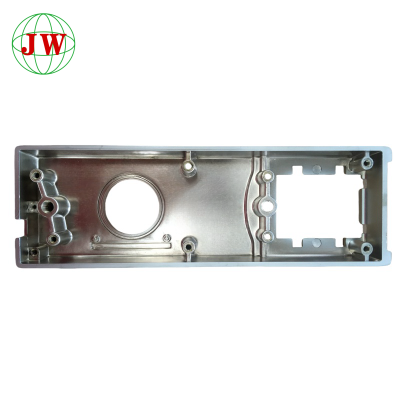

Aluminum components dominate the application of motorcycle die-casting accessories, covering core structural and functional parts. From engine casings and frames to brake pedals and handlebars, aluminum die-casting parts account for over 70% of motorcycle aluminum usage, far exceeding other processing methods <superscript:2. High-strength aluminum alloys such as 6061-T6 and 7075-T6 are widely adopted: 6061-T6 aluminum, with a tensile strength of over 290MPa, is used for frames and swingarms to reduce weight by 10%-15% compared to steel parts; 7075-T6 aluminum, with higher hardness, is applied to brake pedals and footrests to resist wear and deformation <superscript:4. These aluminum components not only enhance maneuverability but also improve fuel efficiency and battery life for electric motorcycles <superscript:4.

Die-casting technology innovation is optimizing the quality of motorcycle die-casting accessories. Intelligent die-casting islands and automated spray robots are widely adopted by leading enterprises, realizing full-process automation from melting to finishing. Zhejiang Xinkemeng Technology Co., Ltd., a key player in the industry, has invested 160 million yuan in smart equipment, improving production efficiency by 50% and ensuring consistent precision of aluminum motorcycle die-casting parts<superscript:3. Vacuum die-casting technology eliminates surface bubbles and internal defects, enabling aluminum components to withstand severe vibrations during off-road riding without cracking <superscript:5.

Green production and recycled materials are reshaping the industry’s development model. With over 70% of aluminum die-casting products used in transportation, enterprises are accelerating the adoption of recycled aluminum <superscript:2. Xinkemeng has built a closed-loop industrial chain covering waste aluminum recycling, smelting, and die-casting, reducing production costs and carbon emissions while maintaining product performance <superscript:3. Surface treatment technologies such as anodizing and powder coating further enhance the corrosion resistance of aluminum components, ensuring they withstand wind, rain, and high-salt environments during long-distance rides<superscript:4.

Market demand is diversifying with the rise of electric and customized motorcycles. Electric motorcycle manufacturers prioritize lightweight aluminum motorcycle die-casting parts to extend battery life, driving demand for integrated motor casings and battery brackets<superscript:4. The customized motorcycle market favors personalized die-casting solutions, with enterprises like Zhanmei Metal providing tailored aluminum components—from retro-style handlebars to high-strength off-road frames—with sample delivery in 7-10 days <superscript:4. Europe and Asia-Pacific are major consumption markets, with China leading global production thanks to mature die-casting technology and cost advantages <superscript:1.

Technological R&D and industrial collaboration are key to competitive advantage. Enterprises are partnering with universities to develop high-performance alloys and precision die-casting molds. Xinkemeng has established a research laboratory at Zhejiang University to tackle core technologies for lightweight aluminum components<superscript:3. Small and medium-sized enterprises focus on niche markets such as precision brake parts, relying on customized die-casting services to gain market share <superscript:1. The integration of digital simulation and MES systems further improves die-casting process stability, reducing defect rates to below 0.5% <superscript:3.

Looking ahead, the aluminum motorcycle die-casting parts industry will focus on lightweight optimization, intelligent production, and green materials. As electric motorcycles and smart riding technologies advance, aluminum components will evolve toward integration and multi-functionality—such as integrated frames with heat dissipation structures <superscript:4. Enterprises mastering core die-casting technology and recycled material utilization will seize market opportunities, driving the motorcycle industry toward safer, more efficient, and sustainable development.

Get the latest price? We'll respond as soon as possible(within 12 hours)