The Advantages of Die Casting in the Automotive Industry

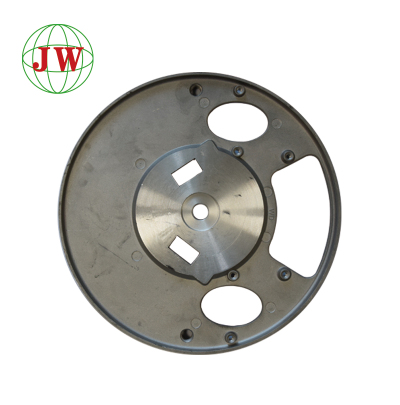

Leveraging advanced die casting technology and precision mold craftsmanship, our automotive die casting parts are crafted from high-strength aluminum alloy, achieving complex structure one-time forming through hot and cold chamber die casting processes with an accuracy of ±0.05mm. These parts are suitable for critical components like engines and chassis.

Our intelligent production line, with an annual output of over 5 million pieces, is equipped with an AI quality inspection system to ensure a pass rate of over 99.5%.

From battery casings for new energy vehicles to transmission connectors for fuel-powered cars, we have provided customized solutions for over 20 global mainstream automakers, with an annual sales growth rate of 35%.

With 15 years of deep expertise in die casting, our R&D team can quickly respond to clients' full-process needs from 3D modeling to mold development, serving as the preferred partner for automotive lightweighting and intelligent upgrading with our lightweight and high-reliability advantages.

Details

Die casting offers several advantages over other manufacturing processes, making it an ideal choice for the automotive industry. Some of the key advantages of die castinginclude:

High Precision and Dimensional Accuracy

Die casting allows for the production of parts with extremely high precision and dimensional accuracy. The high pressure used in the die casting process ensures that the molten metal fills the mold cavity completely, resulting in parts with tight tolerances and consistent dimensions. This is particularly important in the automotive industry, where parts must fit together precisely to ensure the proper functioning of the vehicle.

Die castingcan produce parts with complex geometries that would be difficult or impossible to manufacture using other processes. The ability to create intricate shapes and features allows automotive designers to optimize the performance and functionality of their vehicles. For example, die cast components can be designed to reduce weight, improve aerodynamics, or enhance the strength and durability of the vehicle.

Die casting is a highly automated process that can produce large quantities of parts in a relatively short period of time. The use of robotic handling systems and automated machinery allows for continuous production, reducing labor costs and increasing production efficiency. This is essential in the automotive industry, where high production volumes are required to meet the demands of the market.

Despite the high initial cost of die cast molds, die casting can be a cost-effective manufacturing process for high-volume production. The ability to produce parts with high precision and consistency reduces the need for post-processing operations, such as machining or finishing. Additionally, the use of recyclable materials in die casting can help to reduce production costs and minimize the environmental impact of the manufacturing process.

Die cast components are typically made from high-strength metals such as aluminum, zinc, and magnesium alloys. These materials offer excellent strength, durability, and corrosion resistance, making them ideal for use in automotive applications. Die cast components can withstand the rigors of daily use, ensuring the long-term reliability and performance of the vehicle.

Die Cast Components in the Automotive Industry

Die cast components are used in a wide range of automotive applications, from engine components and transmission parts to body panels and interior trim. Some of the most common die cast components used in the automotive industry include:

Engine Components

Die casting is widely used in the production of engine components, such as cylinder heads, engine blocks, and intake manifolds. These components require high strength, durability, and heat resistance to withstand the harsh operating conditions of the engine. Die cast engine components are typically made from aluminum alloys, which offer excellent thermal conductivity and lightweight properties, helping to improve engine performance and fuel efficiency.

Transmission Parts

Die cast components are also used in the production of transmission parts, such as transmission cases, gear housings, and clutch components. These parts require high precision and strength to ensure smooth and efficient operation of the transmission. Die casting allows for the production of complex transmission parts with tight tolerances, reducing the need for additional machining operations.

Body Panels

In recent years, die casting has become increasingly popular in the production of body panels, such as doors, hoods, and fenders. Die cast body panels offer several advantages over traditional stamped steel panels, including improved strength, durability, and dimensional accuracy. Additionally, die cast body panels can be designed to have complex shapes and features, allowing for greater design flexibility and aerodynamic efficiency.

Interior Trim

Die cast components are also used in the production of interior trim parts, such as door handles, console bezels, and instrument panel frames. These parts require high aesthetic appeal and precision to match the overall design of the vehicle interior. Die casting allows for the production of interior trim parts with smooth surfaces, fine details, and a high-quality finish, enhancing the overall look and feel of the vehicle.

The Future of Die Casting in the Automotive Industry

As the automotive industry continues to evolve, the demand for lightweight, fuel-efficient, and high-performance vehicles is increasing. Die casting is well-positioned to meet these challenges, offering several opportunities for innovation and growth in the future.

Lightweighting

One of the key trends in the automotive industry is lightweighting, which involves reducing the weight of the vehicle to improve fuel efficiency and performance. Die casting can play a crucial role in lightweighting by producing parts from lightweight materials such as aluminum, magnesium, and composite alloys. These materials offer excellent strength-to-weight ratios, allowing for the production of lighter and more efficient vehicles.

Electric Vehicles

The growing popularity of electric vehicles (EVs) is also driving the demand for die casting in the automotive industry. EVs require a large number of high-precision, lightweight components, such as battery casings, electric motor housings, and power electronics enclosures. Die casting is an ideal manufacturing process for these components, offering the necessary precision, strength, and durability.

Advanced Materials and Processes

In addition to lightweighting and EVs, the automotive industry is also exploring the use of advanced materials and processes to improve the performance and efficiency of vehicles. Die casting is likely to benefit from these developments, as new materials and processes are developed to meet the evolving needs of the industry. For example, the use of 3D printing technology in die casting mold production can reduce lead times and costs, while the development of new alloys and composite materials can further enhance the performance of die cast components.

Integration of Smart Technologies

The automotive industry is also moving towards the integration of smart technologies, such as sensors, connectivity, and autonomous driving systems. Die cast components can be designed to accommodate these technologies, providing a platform for the integration of electronics and other components. This will require the development of new die casting processes and technologies to ensure the reliable and efficient production of smart automotive components.

In conclusion, die casting has become an essential technology in the automotive industry, offering numerous advantages in terms of precision, durability, and cost-effectiveness. Die cast components and die cast molds are playing crucial roles in the production of modern vehicles, from engine components and transmission parts to body panels and interior trim. As the automotive industry continues to evolve, the demand for die casting is likely to increase, driven by trends such as lightweighting, electric vehicles, advanced materials and processes, and the integration of smart technologies. The future of die casting in the automotive industry is bright, and it will continue to play a vital role in shaping the vehicles of tomorrow.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)