Aluminum Alloy Furniture Die-Casting Connectors: Revolutionizing Modern Furniture Assembly

2025-08-07 17:38

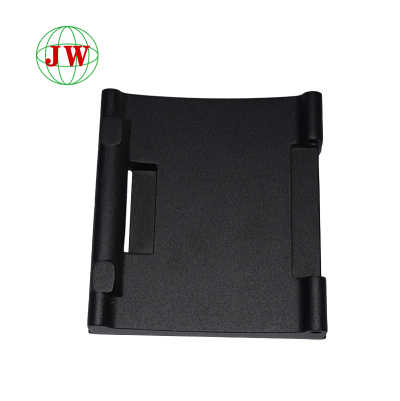

In the dynamic world of furniture manufacturing, aluminum alloy furniture die-casting connectorshave emerged as a game-changing innovation, redefining how furniture pieces are designed, assembled, and sustained. These precision-engineered components, born from advanced die-casting technology, are transforming the industry by combining durability, versatility, and aesthetic appeal—key factors in today’s fast-paced furniture market.

The Rise of Aluminum Alloy in Furniture Connections

Aluminum alloy has become the material of choice for furniture connectors, and for good reason. Its unique blend of properties—lightweight yet strong, corrosion-resistant, and highly malleable—makes it ideal for the rigorous demands of furniture assembly. Unlike traditional materials such as steel, which adds unnecessary weight, or plastic, which lacks long-term durability, aluminum alloys (typically ADC12 or A380) offer a perfect balance.

Furniture die-casting connectors leverage these properties to create components that secure everything from sofa frames and cabinet joints to table legs and bed supports. A single connector can withstand repeated stress, such as the daily opening and closing of a cabinet door or the weight of a person sitting on a chair, without loosening or deforming. This reliability has made them a staple in both residential and commercial furniture, from budget-friendly flat-pack designs to high-end luxury pieces.

How Die-Casting Elevates Connector Performance

The die-casting process is the secret behind the superior quality of these connectors. By injecting molten aluminum alloy into precision-engineered steel molds under high pressure (up to 15,000 psi), manufacturers produce connectors with:

Complex Geometries: Die-casting allows for intricate designs—think threaded inserts, interlocking teeth, and hollow cores—that would be impossible or cost-prohibitive with machining or welding. This enables connectors to fit seamlessly into furniture frames, hiding unsightly hardware and maintaining a clean aesthetic.

Consistent Precision: Each die-cast connector is nearly identical, with tolerances as tight as ±0.02mm. This uniformity is critical for mass-produced furniture, ensuring that components from different batches fit together perfectly during assembly.

Enhanced Strength: The high-pressure process eliminates air bubbles and ensures uniform material distribution, giving aluminum alloy connectors tensile strength up to 280 MPa—strong enough to support heavy loads without bending or breaking.

The Role of Molds in Perfecting Connectors

Behind every high-quality aluminum alloy furniture die-casting connector lies a meticulously crafted mold. These molds, often made from hardened H13 steel, are designed using 3D modeling software to replicate even the smallest details of a connector’s design.

Modern mold-making technologies, such as CNC machining and EDM (electrical discharge machining), ensure that molds can withstand the extreme temperatures (650–700°C) and pressures of die-casting, producing up to 100,000 connectors before needing maintenance. This longevity makes die-casting a cost-effective solution for large-scale production, lowering per-unit costs for manufacturers and, ultimately, consumers.

Mold designers also prioritize functionality. For example, a mold for a sofa frame connector might include channels to allow molten aluminum to flow evenly, preventing weak spots, while a mold for a table leg bracket could feature built-in ejector pins to safely release the finished part without damage.

Advantages for Manufacturers and Consumers

For furniture manufacturers, aluminum alloy die-casting connectors streamline production. Their consistency reduces assembly errors, cutting down on labor costs, while their durability minimizes returns and warranty claims. Modular furniture brands, in particular, benefit—connectors enable quick, tool-free assembly, making it easier for consumers to put together pieces at home.

Consumers, meanwhile, enjoy furniture that lasts longer. A study by the Furniture Industry Research Association (FIRA) found that chairs assembled with aluminum die-cast connectors retained their structural integrity for 10+ years, compared to 3–5 years for those using plastic or wooden dowels. Additionally, the corrosion resistance of aluminum ensures that connectors in outdoor furniture or humid environments (like bathrooms) resist rust and degradation.

Market Trends and Future Innovations

The demand for aluminum alloy furniture die-casting connectors is on the rise, driven by the growing popularity of modular and space-saving furniture. The global furniture hardware market, valued at $8.3 billion in 2023, is projected to grow at a 5.2% annual rate through 2030, with die-cast aluminum connectors accounting for a significant share.

Innovation is fueling this growth. Manufacturers are developing new alloys with enhanced strength-to-weight ratios, while 3D-printed molds are reducing prototyping time from weeks to days, allowing for faster customization. Smart connectors, embedded with sensors to monitor wear and tear, are also on the horizon, promising to alert users when components need maintenance—further extending furniture lifespans.

Conclusion

Aluminum alloy furniture die-casting connectors may be small, but their impact on the furniture industry is profound. By combining the strength of aluminum alloys, the precision of die-casting, and the versatility of advanced molds, they are setting new standards for durability, efficiency, and design. As consumers and manufacturers alike prioritize quality and sustainability, these connectors will continue to play a pivotal role in shaping the future of furniture—one strong, seamless connection at a time.

Get the latest price? We'll respond as soon as possible(within 12 hours)