Unveiling the Power of Die-Cast Components in Architectural Connections: Redefining Structural Integrity and Design Innovation

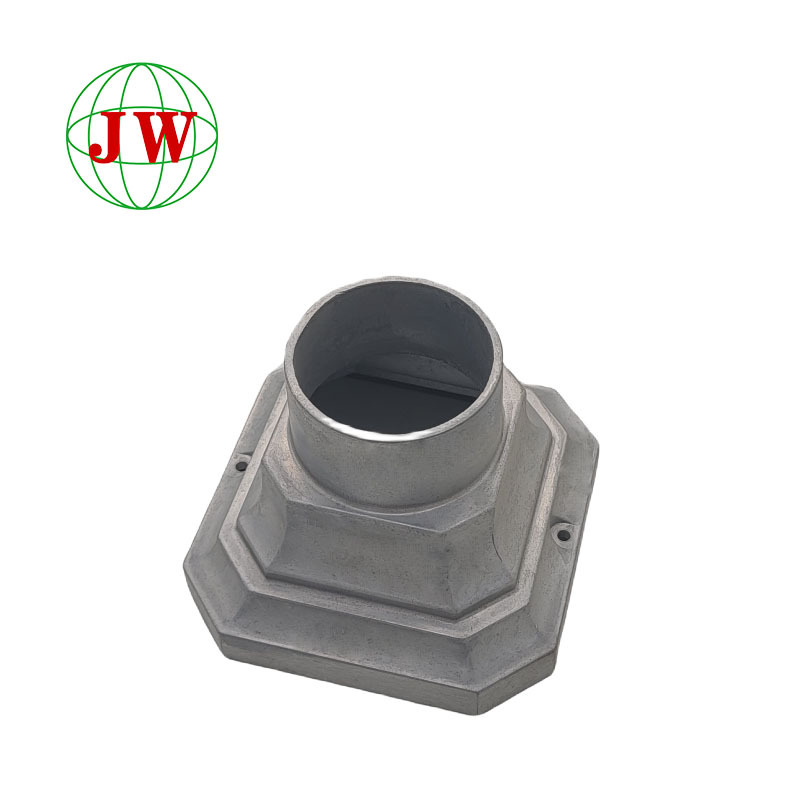

Powered by cutting-edge die-casting technology and precision architectural die-casting connection molds, our architectural die-cast connection accessories are crafted from corrosion-resistant aluminum-zinc alloys, delivering ±0.05mm precision for structural connectors, facade elements, and interior fittings. With annual production capacity of 10 million+ pieces across 500+ specifications, our automated lines integrate AI quality control, ensuring 99.6% pass rates. Serving 40+ global construction giants, projects range from skyscraper beam connectors to sustainable residential facade grilles, generating $30M+ annual revenue. Our R&D team accelerates project timelines with 5-day mold prototyping via 3D printing, while recycled material usage cuts carbon footprints by 35%. Ideal for commercial complexes, bridges, and LEED-certified builds, our die-cast connectors enhance assembly speed by 50% and reduce maintenance costs by 40%, making us the trusted partner for resilient, innovative architecture.

- China

Details

In the dynamic realm of architecture and construction, the pursuit of strength, durability, and aesthetic appeal is unending. Die-casting technologyhas emerged as a transformative force, particularly when it comes to creating robust and versatile architectural die-cast components. These components, crafted with precision using architectural die-casting connection molds, are revolutionizing the way buildings are constructed, offering a seamless blend of functionality and innovation. This comprehensive article explores the myriad benefits, applications, and technological advancements associated with architectural die-cast connection accessories and die-cast connectors in the construction industry.

Understanding the Die-Casting Process for Architectural Applications

At its core, die-casting is a manufacturing process that involves injecting molten metal under high pressure into a mold cavity. For architectural purposes, the architectural die-casting connection molds are meticulously designed to create components with intricate shapes and precise dimensions. Typically made from high-grade tool steel, these molds can withstand the extreme pressures and temperatures during the die-casting process, ensuring consistent and high-quality production of architectural die-cast components.

The process begins with the creation of a digital model of the desired component using advanced computer-aided design (CAD) software. This model serves as the blueprint for the architectural die-casting connection molds, which are then manufactured using computer-aided manufacturing (CAM) techniques. Once the mold is ready, molten metal, commonly aluminum, zinc, or magnesium alloys, is injected into the mold cavity at high pressure. The metal rapidly solidifies, taking on the exact shape of the mold. After cooling, the mold is opened, and the finished architectural die-cast connection accessory is ejected, ready for use in construction projects.

Key Advantages of Architectural Die-Cast Components

Exceptional Strength and Durability

One of the most significant advantages of architectural die-cast components is their remarkable strength and durability. The high-pressure die-casting process results in a dense and uniform structure, making the components highly resistant to mechanical stress, corrosion, and environmental factors. Whether it's a die-cast connector used to join structural steel beams or a decorative element exposed to the elements, these components can withstand the rigors of construction and long-term use, ensuring the structural integrity of buildings.

Precision and Consistency

Precision is paramount in construction, and architectural die-cast connection accessories deliver on this front. Thanks to the accuracy of the architectural die-casting connection molds, each component is produced with exacting tolerances. This consistency ensures seamless integration during construction, reducing the need for time-consuming adjustments and minimizing errors. Whether it's a complex joint for a modern skyscraper or a simple bracket for a residential project, the precision of die-cast components streamlines the construction process.

Design Flexibility

Architectural die-cast components offer unparalleled design flexibility. The die-casting process allows for the creation of intricate shapes, detailed patterns, and complex geometries that would be challenging or impossible to achieve with traditional manufacturing methods. Architects can now bring their most innovative design concepts to life, from ornate facade elements to sleek, modern structural connectors. This flexibility not only enhances the aesthetic appeal of buildings but also enables the optimization of structural performance.

Cost-Effectiveness

While the initial investment in architectural die-casting connection molds may seem substantial, the long-term cost savings of using architectural die-cast connection accessories are significant. The high production speed of the die-casting process allows for mass production, reducing the cost per unit. Additionally, the durability and precision of these components minimize the need for repairs and replacements over the lifespan of a building, resulting in lower maintenance costs.

Diverse Applications of Architectural Die-Cast Components

Structural Connections

In large-scale construction projects, die-cast connectors play a crucial role in ensuring the structural integrity of buildings. These components are used to join various structural elements, such as beams, columns, and trusses, providing a strong and reliable connection. For example, in the construction of bridges and high-rise buildings, die-cast connectors can withstand heavy loads and dynamic forces, ensuring the safety and stability of the structure.

Facade and Exterior Design

The exterior of a building is often its most prominent feature, and architectural die-cast components can enhance its aesthetic appeal. From decorative panels and grilles to intricate brackets and moldings, die-cast components can add a touch of elegance and sophistication to building facades. These components can be customized to match the architectural style of the building, whether it's a historic restoration project or a contemporary design.

Interior Applications

Inside buildings, architectural die-cast connection accessories are used in a variety of applications. They can be found in the form of door and window hardware, handrail fittings, and furniture connectors. These components not only provide functional support but also contribute to the overall interior design, adding a cohesive and stylish look to the space.

Sustainable Construction

With the growing emphasis on sustainable construction, architectural die-cast components offer eco-friendly benefits. Many of the metals used in die-casting, such as aluminum and zinc, are highly recyclable. By using recycled materials in the production of architectural die-cast connection accessories, construction projects can reduce their environmental impact and contribute to a circular economy.

Technological Advancements in Architectural Die-Casting

3D Printing and Rapid Prototyping

The integration of 3D printing technology in the design and development of architectural die-casting connection molds has revolutionized the industry. 3D printing allows for the rapid prototyping of molds, reducing the time and cost associated with traditional mold-making processes. Architects and designers can now quickly test and refine their designs, ensuring that the final architectural die-cast components meet their exact specifications.

Smart Manufacturing and Automation

The advent of smart manufacturing and automation has further enhanced the efficiency and quality of architectural die-casting. Automated die-casting machines equipped with advanced sensors and control systems can monitor and adjust the production process in real-time, ensuring consistent quality and reducing the risk of errors. Additionally, the use of robotics in the handling and assembly of architectural die-cast connection accessories streamlines the production workflow, increasing productivity.

Advanced Materials and Coatings

Continuous research and development in materials science have led to the introduction of advanced alloys and coatings for architectural die-cast components. These new materials offer improved strength, corrosion resistance, and thermal properties, making them suitable for a wider range of applications. For example, specialized coatings can be applied to die-cast connectors to enhance their durability and resistance to harsh environmental conditions.

Choosing the Right Supplier for Architectural Die-Cast Components

When it comes to sourcing architectural die-cast components, selecting the right supplier is crucial. Here are some key factors to consider:

Experience and Expertise

Look for a supplier with a proven track record in the architectural die-casting industry. An experienced supplier will have in-depth knowledge of the construction industry's requirements and be able to provide components that meet the highest standards of quality and performance.

Quality Assurance

Ensure that the supplier has a comprehensive quality assurance program in place. This should include rigorous testing and inspection procedures to verify the strength, durability, and dimensional accuracy of the architectural die-cast connection accessories. A reliable supplier will also be able to provide certification and documentation to support the quality of their products.

Customization Capabilities

Given the diverse design requirements in architecture, choose a supplier that offers customization services. The ability to create bespoke architectural die-casting connection molds and components according to specific project needs is essential for achieving unique and innovative architectural designs.

Sustainability Initiatives

In today's environmentally conscious world, consider suppliers that prioritize sustainability. Look for suppliers that use recycled materials, employ energy-efficient manufacturing processes, and have a commitment to reducing waste and emissions.

In conclusion, architectural die-cast components, including architectural die-cast components, architectural die-casting connection molds, architectural die-cast connection accessories, and die-cast connectors, are at the forefront of innovation in the construction industry. With their exceptional strength, precision, design flexibility, and cost-effectiveness, these components are shaping the future of architecture, enabling the construction of buildings that are not only structurally sound but also visually stunning. As technology continues to advance, the potential for architectural die-casting is limitless, promising even more exciting developments in the years to come.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)