Unleashing the Potential of Die-Cast Furniture Connectors: Revolutionizing the Way We Build and Design

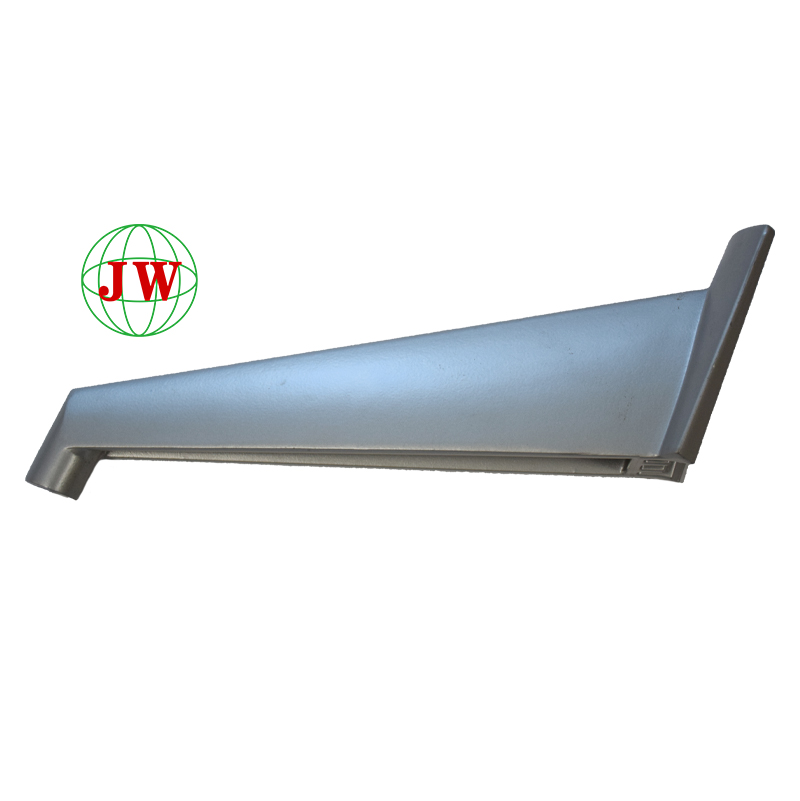

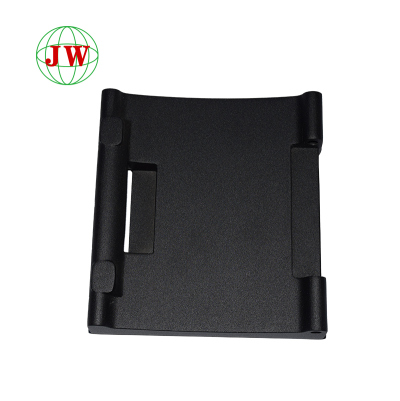

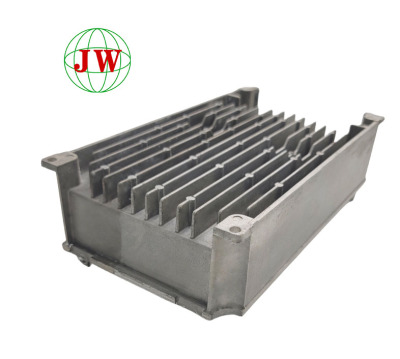

1.Backed by cutting-edge die-casting technology and high-precision die-casting connection molds, our furniture connection die-cast accessories are crafted from high-strength zinc-aluminum alloy, achieving ±0.03mm precision through hot/cold chamber processes. Covering 200+ specifications like modular furniture clips and outdoor table connectors.

2. our smart production lines yield 8 million pieces annually, with 3D visual inspection ensuring a 99.2% pass rate. Serving 30+ global furniture brands, we’ve supplied Nordic minimalist connectors to retro hinges , hitting ¥120 million in annual sales.

3.Our R&D team delivers mold samples within 72 hours, enabling lightweight, weld-free solutions that boost assembly efficiency by 40% .

Details

In the ever-evolving world of furniture manufacturing, innovation is the key to staying ahead. One technology that has been making significant waves in recent years is die casting, particularly when it comes to furniture connectors. Die-cast furniture connectors, along with the precision-engineered die-casting connection molds, are transforming the way furniture is assembled, providing enhanced durability, flexibility, and aesthetic appeal. This article delves deep into the world of furniture connection die-cast accessories, exploring their benefits, applications, and the cutting-edge technology behind them.

The Basics of Die Casting for Furniture Connectors

Die casting is a manufacturing process that involves injecting molten metal under high pressure into a mold cavity. The result is a precisely formed part with intricate details and consistent quality. When it comes to furniture, die-cast connectors are used to join various components together, ensuring a sturdy and long-lasting connection.

The process begins with the design of the die-casting connection mold. These molds are typically made from high-strength steel and are engineered to withstand the intense pressure and temperature of the die-casting process. Using advanced computer-aided design (CAD) software, designers can create moldsthat are tailored to the specific requirements of the furniture connector, whether it's a simple bracket or a complex interlocking mechanism.

Once the mold is ready, molten metal, usually aluminum or zinc alloy, is injected into the mold cavity. The high pressure ensures that the metal fills every corner of the mold, resulting in a part with tight tolerances and excellent dimensional accuracy. After the metal has cooled and solidified, the mold is opened, and the furniture connection die-cast accessory is ejected, ready for further processing or assembly.

The Advantages of Die-Cast Furniture Connectors

Unparalleled Durability

One of the primary advantages of die-cast furniture connectors is their exceptional durability. The high-pressure die-casting process results in a dense and uniform structure, making the connectors resistant to wear, tear, and deformation. Whether it's a heavy-duty table leg connector or a hinge for a frequently used cabinet door, die-cast connectors can withstand the rigors of daily use, ensuring that your furniture lasts for years to come.

Precision and Consistency

Thanks to the precision of the die-casting connection molds, each furniture connection die-cast accessory is produced with the same high level of accuracy. This consistency is crucial in furniture manufacturing, as it allows for easy assembly and ensures that all components fit together perfectly. There's no need for time-consuming adjustments or modifications, saving both time and labor costs during the production process.

Design Flexibility

Die casting offers unparalleled design flexibility when it comes to furniture connectors. With the ability to create complex geometries and intricate details, designers can bring their most innovative ideas to life. From sleek, modern connectors with smooth curves to ornate, decorative pieces that add a touch of elegance, die-cast connectors can be customized to suit any furniture style or design concept.

Cost-Effectiveness

While the initial investment in die-casting connection molds may be high, the long-term cost savings of using die-cast furniture connectors are significant. The high production speed of the die-casting process allows for large-scale manufacturing, reducing the cost per unit. Additionally, the durability and precision of die-cast connectors mean fewer product failures and returns, further saving on costs associated with repairs and replacements.

Applications of Die-Cast Furniture Connectors

Modular Furniture

In the world of modular furniture, die-cast furniture connectors are indispensable. These connectors enable easy assembly and disassembly of furniture units, allowing users to customize their living spaces according to their needs. Whether it's a modular shelving system that can be expanded or reconfigured, or a set of stackable chairs for a flexible dining area, die-cast connectors provide the strength and stability required for modular designs.

Outdoor Furniture

Outdoor furniture is exposed to harsh weather conditions, from scorching sun to heavy rain and snow. Die-cast furniture connectors, especially those made from corrosion-resistant materials like aluminum alloy, are perfect for outdoor applications. They can withstand the elements without rusting or deteriorating, ensuring that your outdoor furniture remains functional and attractive for years. Whether it's a patio set, a garden bench, or a poolside lounger, die-cast connectors provide the reliability needed for outdoor use.

High-End Furniture

For high-end furniture manufacturers, attention to detail and quality are paramount. Die-cast furniture connectors offer the perfect combination of functionality and aesthetics. Intricately designed die-cast connectors can be used as decorative elements, adding a touch of luxury to furniture pieces. From ornate drawer pulls to elegant cabinet hinges, die-cast connectors can enhance the overall look and feel of high-end furniture, making it stand out in the market.

The Technology Behind Die-Cast Furniture Connectors

Advanced CAD/CAM Design

As mentioned earlier, computer-aided design (CAD) and computer-aided manufacturing (CAM) play a crucial role in the production of die-cast furniture connectors. CAD software allows designers to create detailed 3D models of the connectors, optimizing their design for strength, functionality, and aesthetics. CAM technology then translates these digital designs into physical die-casting connection molds, ensuring that the molds are manufactured with the highest level of precision.

High-Pressure Die-Casting Machines

The heart of the die-casting process is the high-pressure die-casting machine. These machines are designed to inject molten metal into the mold cavity at extremely high pressures, ensuring that the metal fills every nook and cranny of the mold. Modern die-casting machines are equipped with advanced control systems that can regulate the pressure, temperature, and injection speed, allowing for consistent and high-quality production of furniture connection die-cast accessories.

Quality Control Measures

To ensure that every die-cast connector meets the highest standards of quality, strict quality control measures are implemented throughout the production process. From inspecting the raw materials to conducting thorough tests on the finished products, manufacturers use a variety of techniques, including non-destructive testing and dimensional analysis, to ensure that the connectors are free from defects and meet the required specifications.

Choosing the Right Die-Cast Furniture Connector Supplier

When it comes to sourcing die-cast furniture connectors, choosing the right supplier is crucial. Here are some factors to consider:

Experience and Expertise

Look for a supplier with a proven track record in the die-casting industry. An experienced supplier will have the knowledge and expertise to produce high-quality connectors that meet your specific requirements. They will also be able to offer valuable insights and suggestions on design, material selection, and production processes.

Quality Assurance

Ensure that the supplier has a robust quality assurance system in place. This includes regular inspections, testing, and certification to ensure that the furniture connection die-cast accessories meet international quality standards. A reliable supplier will also be able to provide you with detailed quality reports and documentation.

Customization Options

If you have specific design requirements for your furniture connectors, choose a supplier that offers customization services. A good supplier will be able to work with you to create custom die-casting connection molds and produce connectors that are tailored to your unique needs.

Competitive Pricing

While quality should be your top priority, it's also important to find a supplier that offers competitive pricing. Compare quotes from different suppliers to ensure that you're getting the best value for your money without compromising on quality.

In conclusion, die-cast furniture connectors are a game-changer in the furniture manufacturing industry. With their exceptional durability, precision, design flexibility, and cost-effectiveness, they are the ideal choice for furniture manufacturers looking to create innovative, high-quality products. By understanding the technology behind these connectors and choosing the right supplier, you can unlock the full potential of die-cast furniture connectors and take your furniture designs to the next level. Whether you're a small-scale furniture maker or a large-scale manufacturer, die-cast furniture connectors are sure to be a valuable addition to your production process.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)