Outstanding Die-Casting Products: Meeting Stringent Standards

2025-06-12 15:00

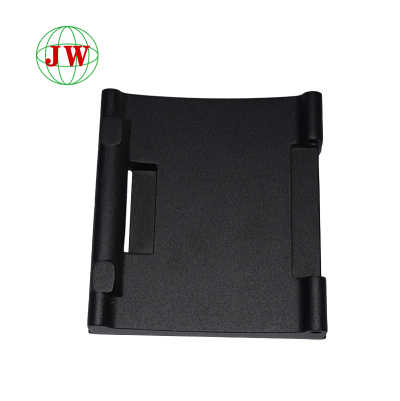

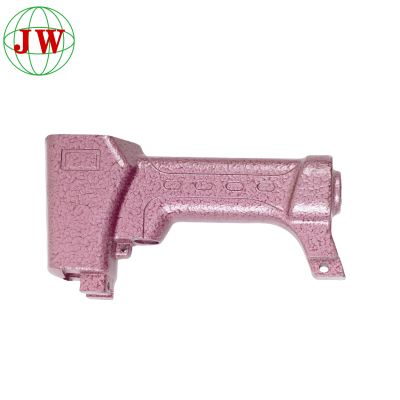

In the competitive landscape of modern manufacturing, die-casting products have emerged as paragons of precision and reliability, catering to industries where quality and consistency are non-negotiable. From automotive components to aerospace parts, these products embody the perfect fusion of advanced engineering and robust materials, ensuring they meet the most stringent international standards. Our die-casting products stand out for their exceptional durability, dimensional accuracy, and versatility, making them the go-to solution for manufacturers seeking excellence.

The Pinnacle of Precision Engineering

Die-casting is a manufacturing process that injects molten metal under high pressure into custom molds, yielding components with intricate details and tight tolerances. What sets our die-casting products apart is the meticulous attention to detail at every stage—from mold design to material selection. Using state-of-the-art computer-aided design (CAD) and simulation tools, we optimize each product for performance, ensuring it withstands mechanical stress, thermal fluctuations, and environmental factors.

Our die-casting products are crafted using premium alloys, including aluminum, zinc, and magnesium. For instance, aluminum alloys offer a superior strength-to-weight ratio, making them ideal for automotive parts that require both lightness and durability. Zinc alloys, meanwhile, excel in producing components with fine surface finishes and complex geometries, perfect for consumer electronics and decorative elements. Each material is rigorously tested to ensure compliance with standards like ISO 9001 and ASTM, guaranteeing consistency batch after batch.

Uncompromising Quality and Durability

Durability lies at the core of our die-casting products. The high-pressure casting process results in dense, void-free structures that resist wear, corrosion, and deformation. For example, our automotive die-casting products—such as engine blocks and transmission housings—undergo rigorous stress testing to simulate real-world conditions, ensuring they perform flawlessly even under extreme loads.

Surface finishes further enhance product longevity. Many of our die-casting products feature specialized coatings like anodizing, powder coating, or electroplating, which not only improve corrosion resistance but also meet aesthetic requirements. In aerospace applications, where components must withstand harsh environments, these finishes are critical for maintaining performance over decades.

Versatility Across Industries

The adaptability of our die-casting products makes them indispensable across diverse sectors:

Automotive Industry: Lightweight die-casting products like engine mounts and suspension components improve fuel efficiency while enhancing safety. Their precision ensures seamless integration with other parts, reducing assembly errors.

Aerospace: High-strength aluminum die-casting products are used in aircraft structures and engine components, where every gram of weight saved matters for fuel economy.

Consumer Electronics: Zinc alloy die-casting products form sleek, durable casings for smartphones and laptops, combining aesthetic appeal with protection for internal components.

Industrial Machinery: Heavy-duty die-casting products withstand continuous operation in factories, from gear housings to hydraulic manifolds.

Advanced Technology and Quality Control

Our commitment to excellence is reinforced by cutting-edge technology. High-pressure die-casting machines with automated controls ensure consistent injection pressure and temperature, minimizing defects. 3D printing allows rapid prototyping, enabling us to test and refine designs before mass production—reducing lead times and costs.

Quality control is non-negotiable. Every die-casting product undergoes rigorous inspection, including:

Dimensional checks using coordinate measuring machines (CMMs)

Non-destructive testing (NDT) for internal defects

Mechanical property tests for strength and ductility

Corrosion resistance assessments in salt spray chambers

This thorough process ensures that only products meeting or exceeding industry standards reach our clients.

Sustainable Manufacturing Practices

In addition to performance, our die-casting products align with sustainable manufacturing goals. Aluminum and zinc are highly recyclable, and we prioritize using recycled materials where possible. Energy-efficient casting processes and waste reduction initiatives further minimize our environmental footprint, making our products an eco-friendly choice for green manufacturing initiatives.

Meeting Global Standards, Driving Innovation

Whether it’s a precision medical device component or a heavy-duty industrial part, our die-casting products are engineered to exceed expectations. By staying at the forefront of material science and casting technology, we continue to develop solutions that meet evolving industry standards—from the rigorous demands of the automotive sector to the precision requirements of electronics.

In a world where quality is non-negotiable, our die-casting products stand as a testament to what’s possible when engineering, materials, and innovation converge. They aren’t just components; they’re the building blocks of reliable, high-performance systems that drive industries forward.

Get the latest price? We'll respond as soon as possible(within 12 hours)