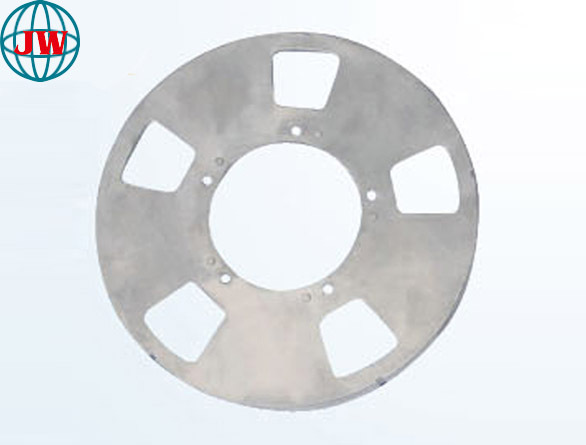

Aluminum Die Casting For Communication Connector

1.From product mold design and manufacturing, die casting, CNC processing, surface treatment one-stop production,The cost can be reduced by 30%

2.Can be produced according to customer's specified materials, our company has the ability to prepare special aluminum alloy materials

3.High precision aluminum alloy die casting, controllable tolerance+-0.02

4.2 days sample preparation, 20 days fast delivery, efficient supply capacity of 300 tons of materials per month.

5.The density of die casting finished products is uniform, the products are not easy to break, deform, and stable in quality

6.Online customer service one-by-one to solve your problems

7.Advanced production corollary equipment

Details

Aluminum casting alloys is a metal processing process that melts aluminum alloy and injects it into a mold, uses high pressure to fill the mold cavity with aluminum liquid, and cools and solidifies it into shape. This process has the advantages of short production cycle, high production efficiency, and relatively low cost, and is suitable for mass production of high-precision, complex-structured aluminum alloy parts. In the manufacturing of communication connectors, aluminum casting alloys technology can produce connector parts with excellent mechanical properties and good appearance, meeting the quality, precision and reliability requirements of communication equipment.

Aluminum mold casting refers to melting aluminum alloy and injecting it into a metal mold, and using high pressure to compact the aluminum liquid to form aluminum alloy parts with high precision and complex structure. This process is suitable for producing large quantities of connector parts and has the advantages of high production efficiency, low cost, and stable product quality. Aluminum casting refers to melting aluminum alloy and pouring it into a sand mold or metal mold, and solidifying it through natural cooling to form aluminum die casting. Aluminum casting products usually have lower costs than die-cast products and are suitable for producing some simple structures or small batches of connector parts.

In aluminum casting alloys and aluminum casting, commonly used aluminum casting alloys include A380, A360, ADC12, etc. These aluminum casting alloys have certain mechanical properties, corrosion resistance and processing properties, and are suitable for the manufacture of precision components such as communication connectors. Among them, A380 alloy has good fluidity and heat resistance, and is suitable for connector parts that require high precision and complex structures; A360 alloy has good mechanical properties and corrosion resistance, and is suitable for product strength and durability requirements. Higher connector parts; ADC12 alloy has good heat resistance and lubricity, and is suitable for manufacturing connector parts in high temperature environments.

Aluminum die casting technology has many advantages in communication connector manufacturing. Firstly, it has high molding precision, which can produce connector parts with complex shapes and precise dimensions, ensuring the assembly and use performance of the connector; secondly, it has high production efficiency, which can quickly meet market demand and improve production efficiency and product competitiveness; thirdly, it has high production efficiency. The first is stable product quality, which can ensure the stability and reliability of the connector and reduce product quality risks; the last is the relatively low cost, which can reduce the production cost of the connector and improve the economic benefits of the enterprise.

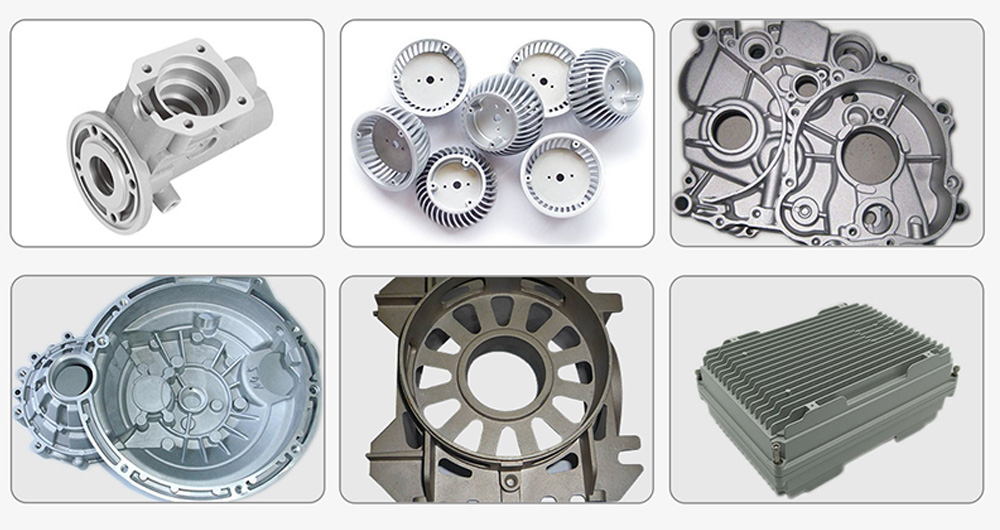

JiaWei casting Co.,Ltd. , founded in 1992, is one of the leading aluminum casting companies/manufacturers in China. We have more than 30-year experience in aluminum casting. We specialize in producing fully machined, finished and tested aluminum castings. We have more than 120 well-trained staff, a team committed to customer satisfaction, good quality and constant innovation. We are OEM aluminum casting manufacturer in China. We welcome orders no matter big or small, and we are confident providing our customers high quality products. Our aluminum casting products cover automotive parts, pump/valve components, light fixture parts, patio/outdoor furniture parts, architecture parts, medical equipment parts, marine parts, electrical enclosures, pipe fittings, heat sinks, hydraulic parts etc. Most of our products are exported to American, European, Australian and Asian market, and have won good reputation among our customers. If our customer needs prototypes for product test, we are able to manufacture these in very short timescale utilizing CNC machining from solid. We also have an in-house tooling workshop to design, manufacture and repair tooling.

Sample Case:

Product Material: environment-friendly aluminum alloy ADC12, ADC1, A380, A360, Alsi9cu3, Alsi12Cu1Fe, LM25, etc.,We can customize the materials specified by customers

Surface Treatment: ultrasonic cleaning, vibration, grinding, polishing, sand blasting, painting, powder spraying, electroplating, oxidation, etc.

Workshop Display:

| ||

| Die Casting Workshop | ||

|  |  |

| CNC Finishing Workshop | Testing Center | Mold Workshop |

Surface Treatment

|  |  |

| TM Wave | Grind | Polishing |

|  |  |

| Ultrasonic Cleaning | Sandblasting | Painting and powder spraying |

Product Tag

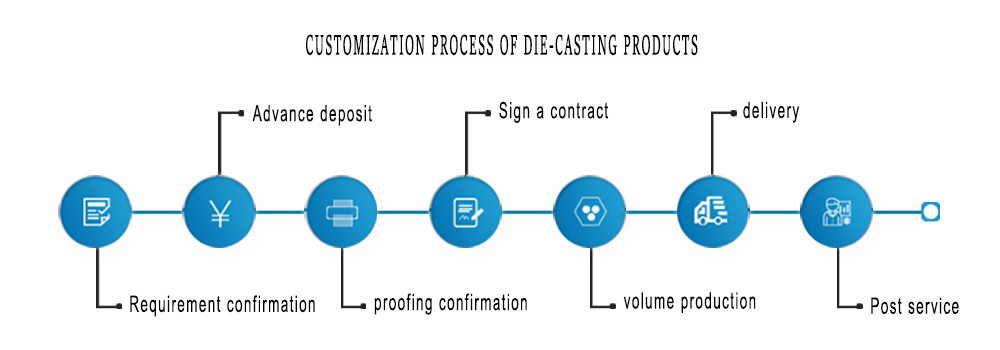

Get the latest price? We'll respond as soon as possible(within 12 hours)