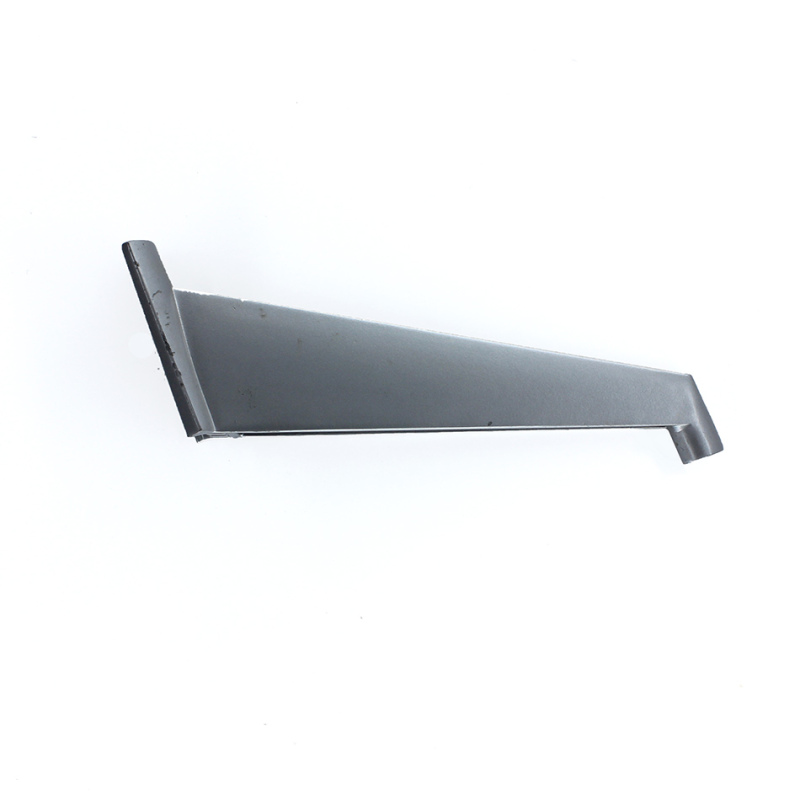

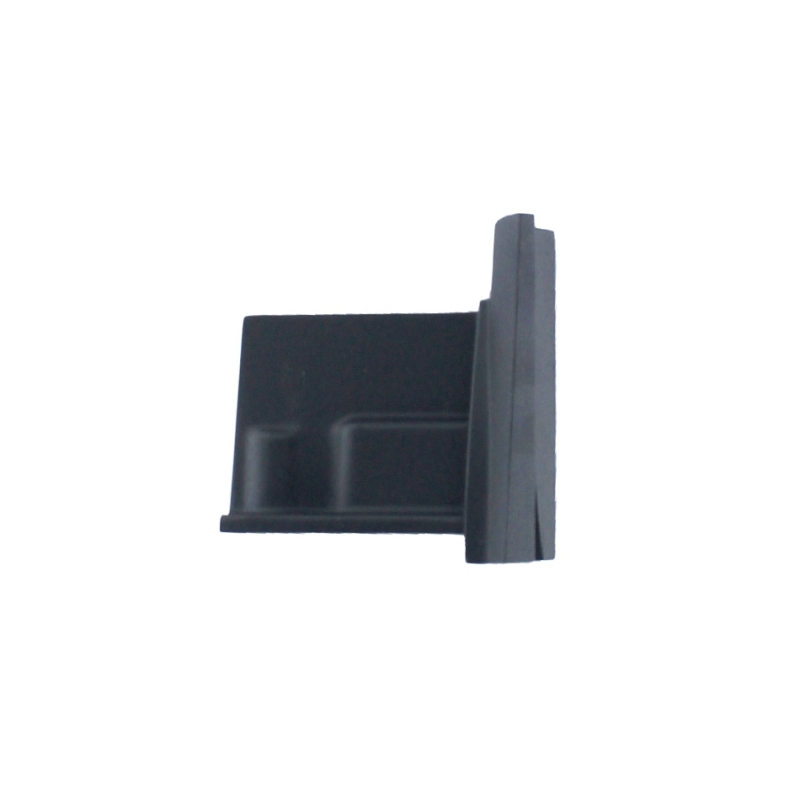

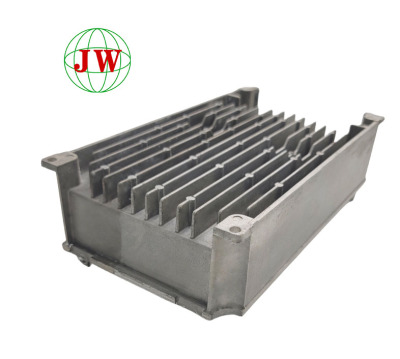

Die cast aluminum outdoor furniture

1.From mold design-mold production, one-stop service. 15-day mold opening, 3-day sample, 7-day delivery, efficient docking

2.Can be produced according to customer's specified materials, our company has the ability to prepare special aluminum alloy materials

3.The density of die casting finished products is uniform, the products are not easy to break, deform, and stable in quality

4.30-year experience in aluminum tooling‘s factory with 2000+ tooling designs

5.Monthly inspection, inventory, maintenance, and upkeep of all molds

6.Tonnage of die-casting machine :160T to 800T

7.Strict product quality inspection, layer by layer control

Details

JiaWei casting Co.,Ltd. , founded in 1992, is one of the leading aluminum casting companies/manufacturers in China. We have more than 30-year experience in aluminum casting. We specialize in producing fully machined, finished and tested aluminum castings. We have more than 120 well-trained staff, a team committed to customer satisfaction, good quality and constant innovation. We are OEM aluminum casting manufacturer in China. We welcome orders no matter big or small, and we are confident providing our customers high quality products. Our aluminum casting products cover automotive parts, pump/valve components, light fixture parts, patio/outdoor furniture parts, architecture parts, medical equipment parts, marine parts, electrical enclosures, pipe fittings, heat sinks, hydraulic parts etc. Most of our products are exported to American, European, Australian and Asian market, and have won good reputation among our customers. If our customer needs prototypes for product test, we are able to manufacture these in very short timescale utilizing CNC machining from solid. We also have an in-house tooling workshop to design, manufacture and repair tooling.

OUR WORKFLOW

In our aluminum foundry, the casting journey from inquiry to delivery is processed step by step as below. In this journey, what satisfy and impress our customers is not only quality aluminum castings, but also our professional services.

1

Inquiry

You have a product to produce, and some components of your product are identified to be aluminum castings. You send us drawings, samples or even rough schetches for inquiry.

2

Technical Clarification

We work with you to develop 3D models, fix casting process and finishing process. We advise on suitable materials, draft angles, wall thicknesses, achievable tolerances etc.

3

Quotation

After technical clarification, we calculate mold cost, material cost, casting cost, machining cost, finishing cost, inspection cost, packing cost, logistic cost etc. and offer you a competitive price.

4

Samples

After you place order to us, we prepare samples for confirmation. If you need prototypes for product test, we are able to manufacture these by using CNC machining in short timescale.

5

Mass Production

After product test, we start mass production. According to required delivery date, we make reasonable production plan to realize seamless connection between different processes.

6

Packing & Delivery

After final inspection, we pack the finished castings in accordence with our customers’ request and the international transportation standard. We deliver the well-packed castings to port.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)