2025 Furniture Die-Casting Connectors: Precision, Aesthetics and Global Demand Drive Industry Upgrade

2026-01-26 15:30

The global furniture die-casting connector industry is ushering in a new round of growth in 2025, fueled by the rising demand for smart home furniture, the pursuit of product durability, and the advancement of die casting technology. As core components linking furniture structures, die-casting connectors are breaking the traditional positioning of "functional accessories" and evolving toward high precision, multi-material integration, and aesthetic integration. According to China Report Hall, the global furniture hardware connector market size is expected to exceed $18 billion in 2025, with die-casting products accounting for over 55% due to their superior structural stability <superscript:1.

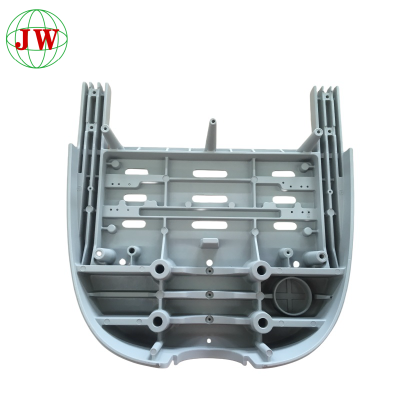

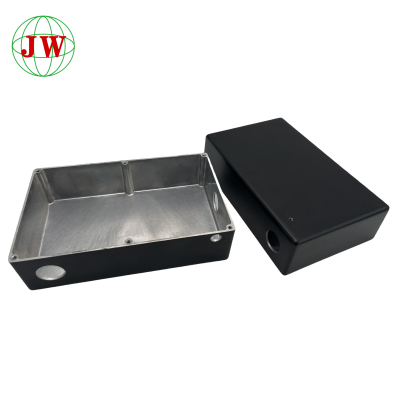

Material innovation has become a key driver of product upgrading in the industry. Zinc alloy and aluminum alloy are the mainstream materials for furniture die-casting connectors, each with unique advantages. Zinc alloy, represented by Zamak 3 and Zamak 5, boasts excellent die casting performance, enabling the production of complex, thin-walled precision parts with smooth surfaces, and can undergo multiple surface treatments such as electroplating and spraying <superscript:2. Aluminum alloy connectors, on the other hand, are favored in lightweight furniture due to their high strength, corrosion resistance, and precise dimensional control, perfectly matching the demand for modern minimalist dining tables and chairs <superscript:4. Dongguan Xiongsheng Hardware, a leading enterprise, has established 12 process standards for mainstream materials, strictly controlling raw material lead content below 0.03% to ensure product durability <superscript:5.

Technological iteration is optimizing the production efficiency and precision of die-casting connectors. Enterprises are increasingly adopting intelligent die casting equipment and modular production systems to address seasonal order fluctuations. Xiongsheng Hardware has realized 2-hour rapid material switching between zinc and aluminum with 10 core devices, and shortened the die casting mold development cycle from 7 days to 2 days through prefabricated standard mold bases <superscript:5. Meanwhile, MES systems are widely used in the die casting process to monitor filling speed in real time, controlling deviations within ±0.1m/s, and three-coordinate measuring instruments with ±0.003mm precision ensure that each connector meets strict dimensional requirements <superscript:5.

Aesthetic integration and customization have become new competitive focuses. Modern furniture pays more attention to the overall style unity, prompting die-casting connectors to move beyond pure functionality. Enterprises like Dihui Die Casting integrate design sense into connectors, through sophisticated polishing and spraying treatments, creating a delicate textured surface that enhances the furniture’s fashion and elegance <superscript:4. Customized services are also expanding—manufacturers can tailor die casting solutions according to different furniture styles, optimizing connector structure for easy installation and disassembly while ensuring stability<superscript:4. This customization capability is particularly popular in the European and American markets, where DIY culture prevails <superscript:6.

Global market demand shows strong growth momentum, with Asia-Pacific as the core supply and demand hub. Chinese enterprises, relying on mature die casting technology and cost advantages, occupy an important position in the global supply chain. Xiongsheng Hardware’s products are exported to Germany, Italy, Japan and other countries, and it provides OEM services for several Japanese brands, winning recognition with high quality and reasonable prices <superscript:3. The Middle East market, driven by infrastructure investment, has seen an 8.3% growth in demand for structural connectors, while the Southeast Asian market’s demand for furniture hardware is growing at over 20% due to demographic dividends <superscript:6.

Sustainability and quality control are becoming industry development thresholds. Enterprises are strengthening environmental management in the die casting process, adopting energy-saving equipment and recycling systems to reduce carbon emissions. Xiongsheng Hardware adheres to a three-level inspection system, from raw material spectrum detection to finished product full inspection, ensuring a 99.2% product qualification rate <superscript:5. Meanwhile, compliance with international standards such as ISO9001 has become a basic requirement for enterprises to enter the global market, promoting the industry’s standardized development.

Looking ahead, the furniture die-casting connector industry will focus on intelligent upgrading, material innovation and global layout. With the deep integration of smart home and customized furniture trends, die casting technology will continue to break through, making connectors more precise, durable and aesthetically pleasing. Enterprises that grasp the balance between efficiency, quality and design will gain a competitive edge in the global market, driving the industry toward high-end, sustainable development.

Get the latest price? We'll respond as soon as possible(within 12 hours)